Designed For IKEA

Designed for a 14-week project at ArtCenter College of Design. Skills acquired during this project

3D modelling

Design for manufacturing

Product research

Material sourcing

Conducting user research

Keyshot

Designing for a brand

Woodworking

Mechanical design

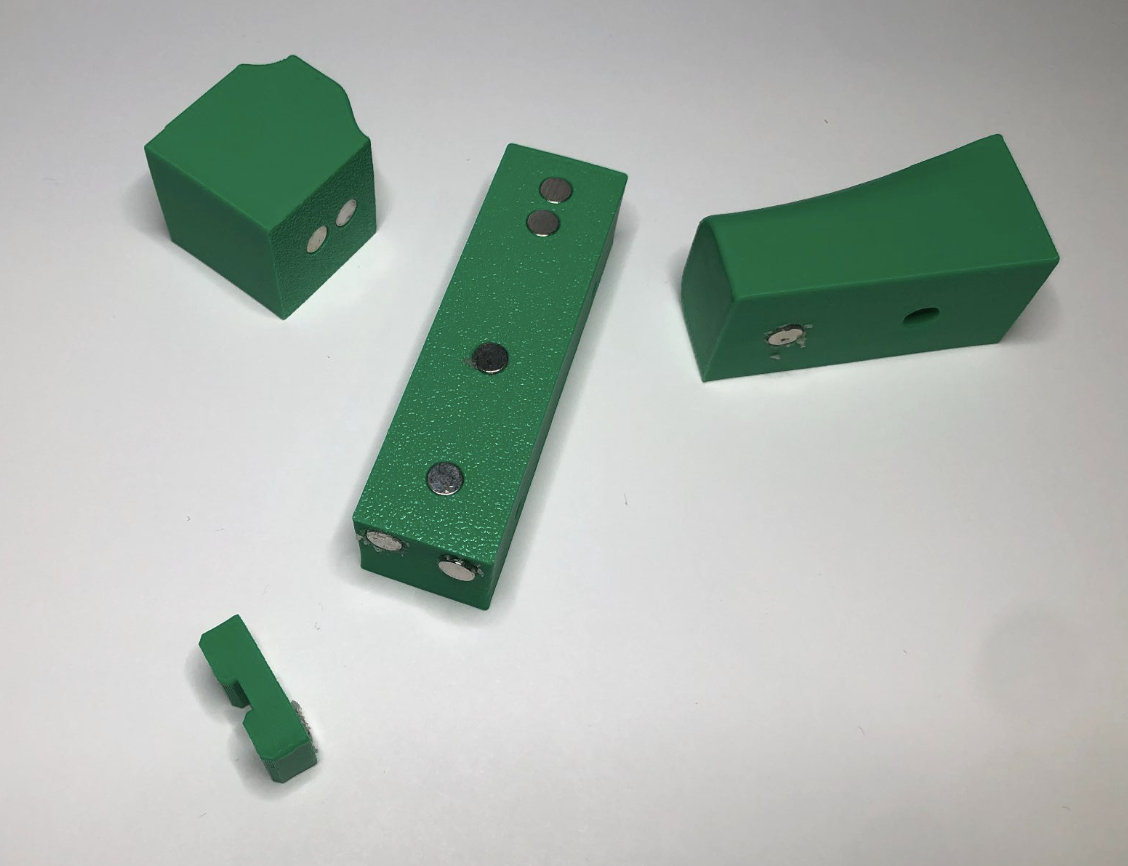

How It Works

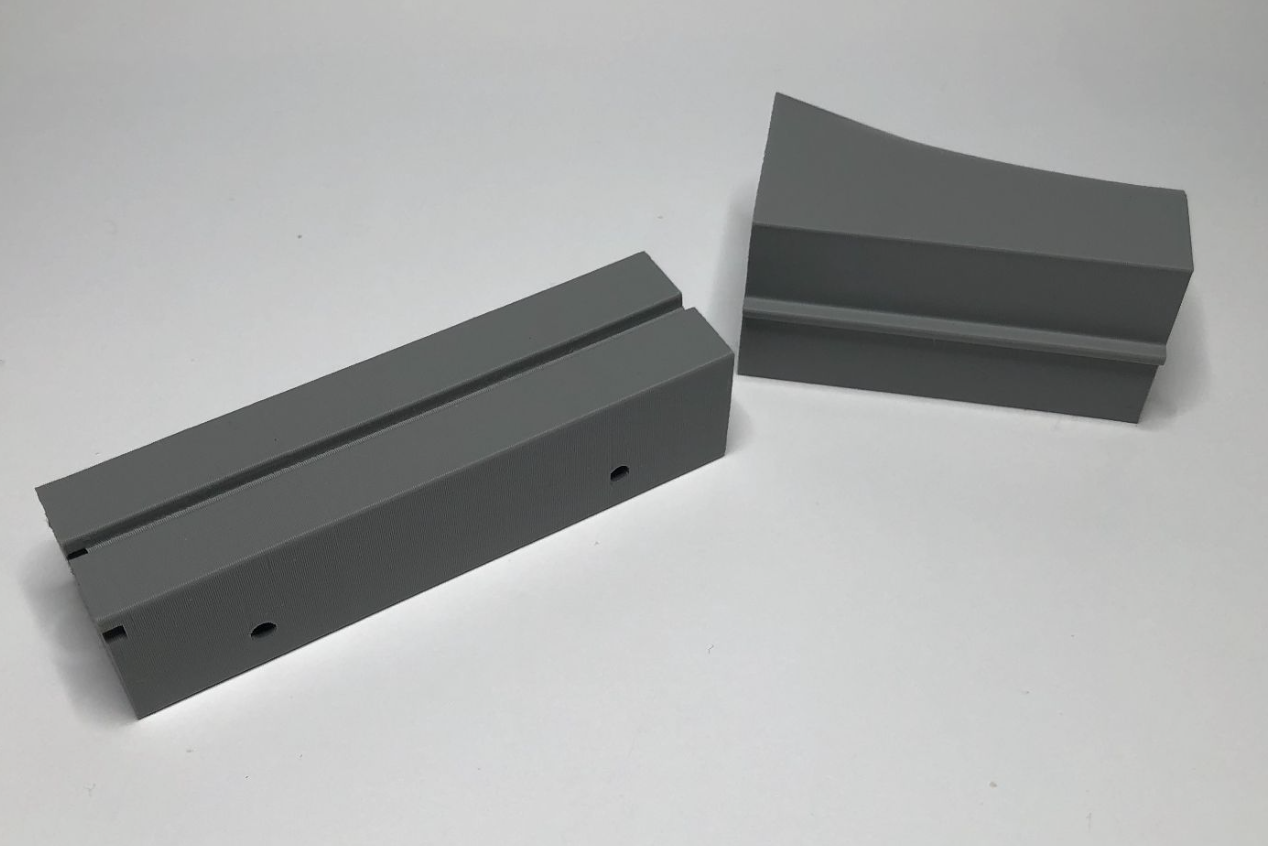

Train components snap together through a combination of magnets and keyways

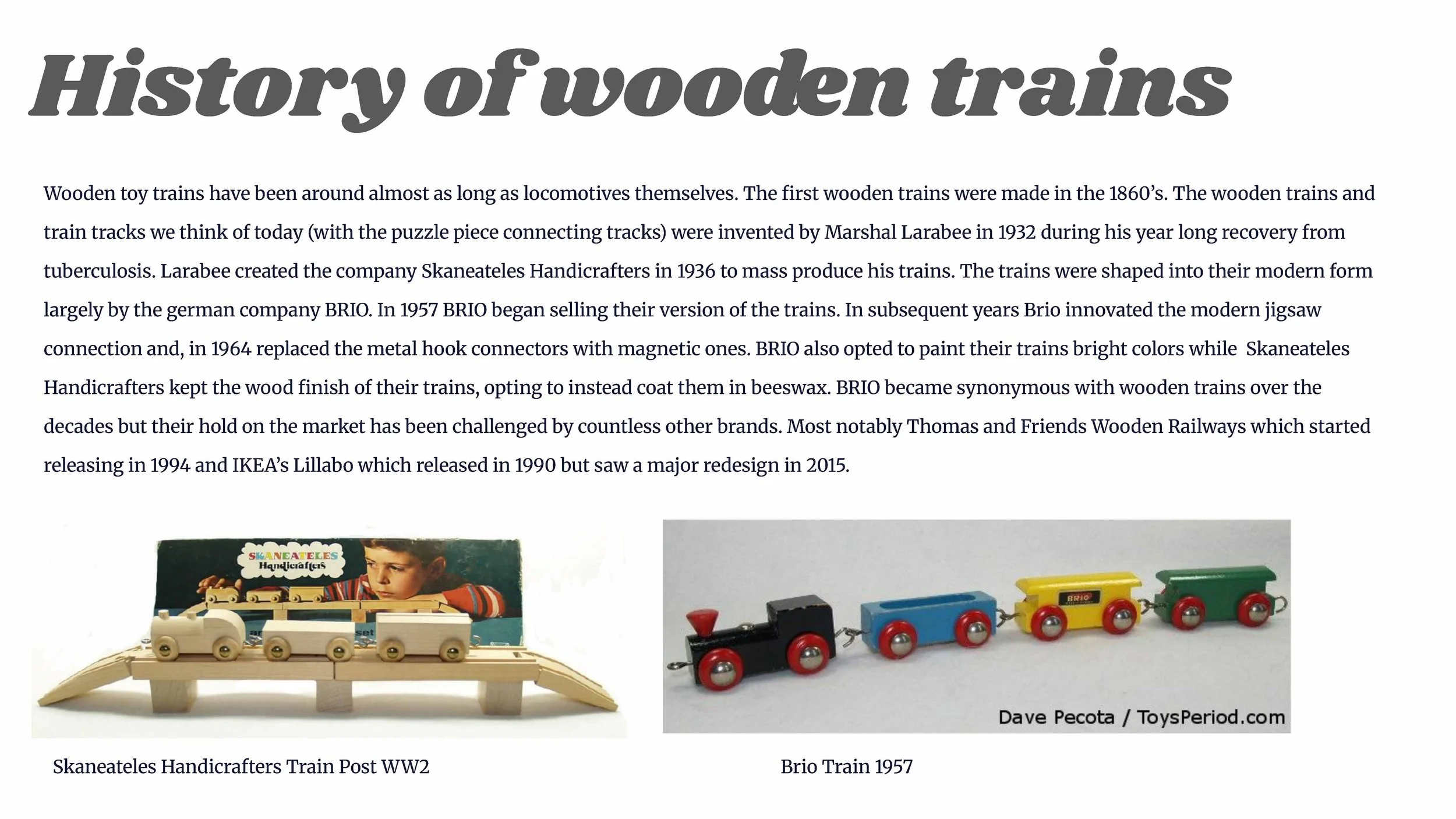

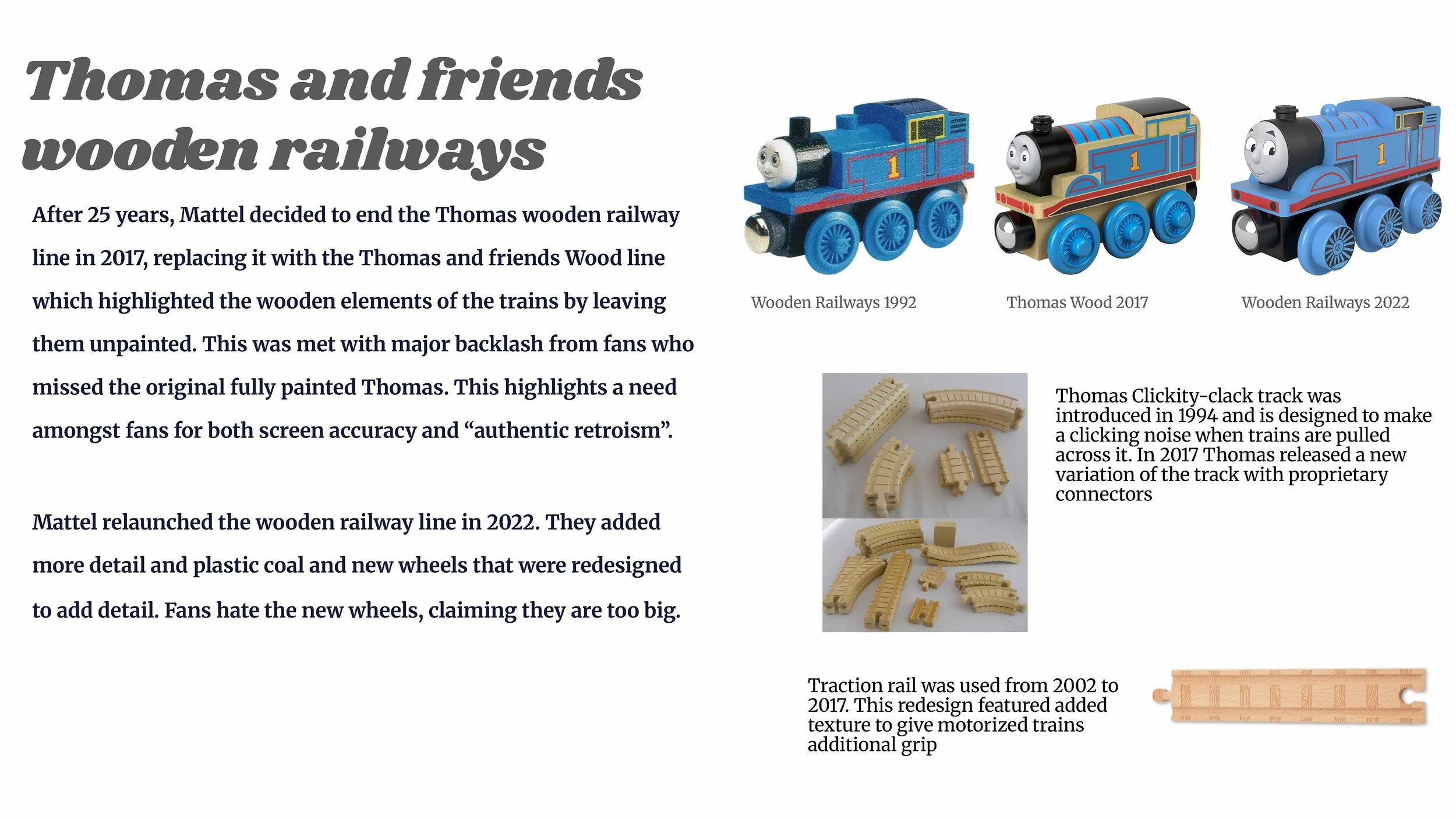

Wooden train reference

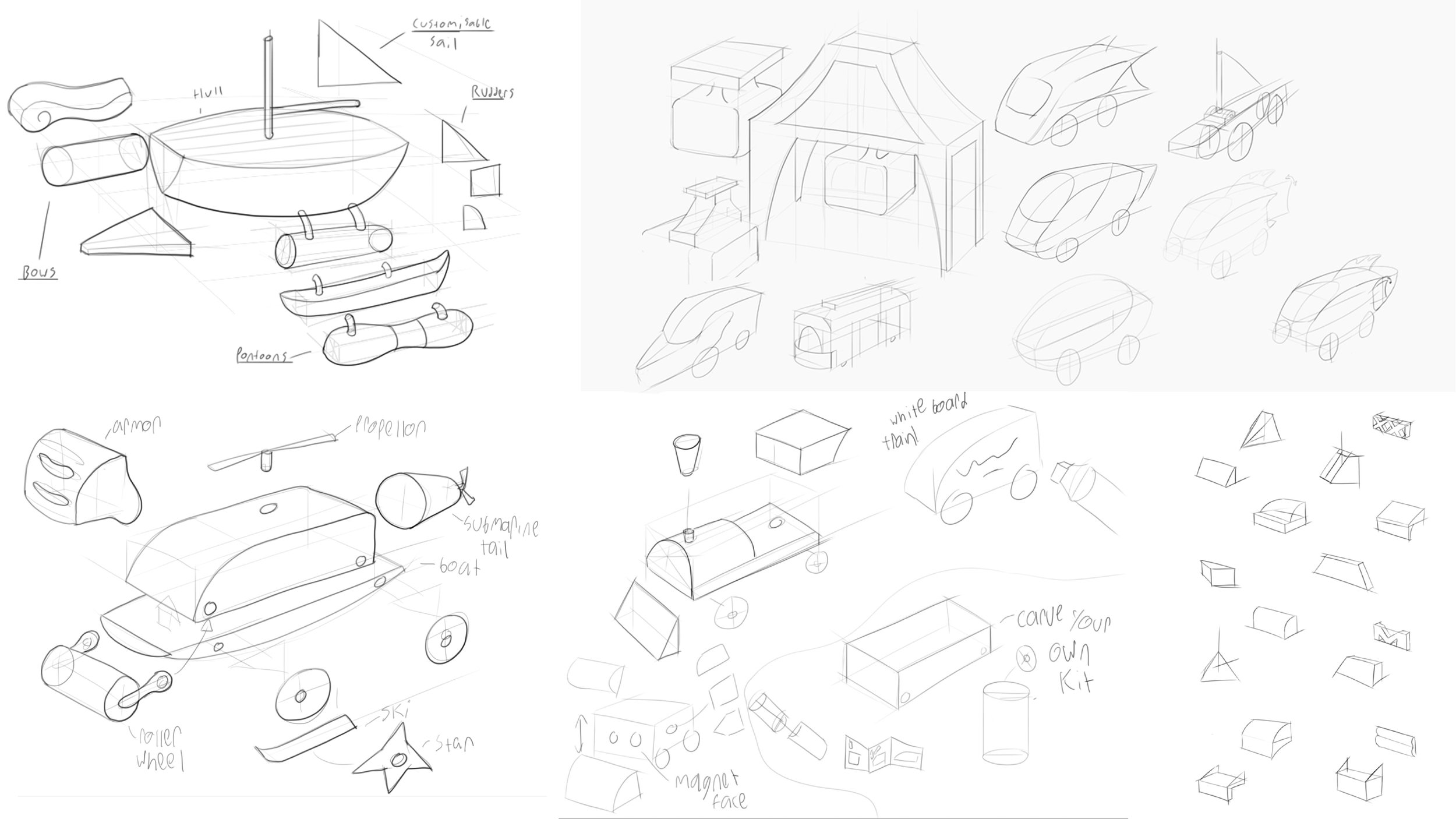

Concept Sketch

Project Origins

I originally pitched and developed the buildable train concept outside of school for a local theater (Arroyo Repertory Theater) to do a community outreach project for the holiday season. The idea was to design and manufacture wooden trains for kids to customize and paint themselves.

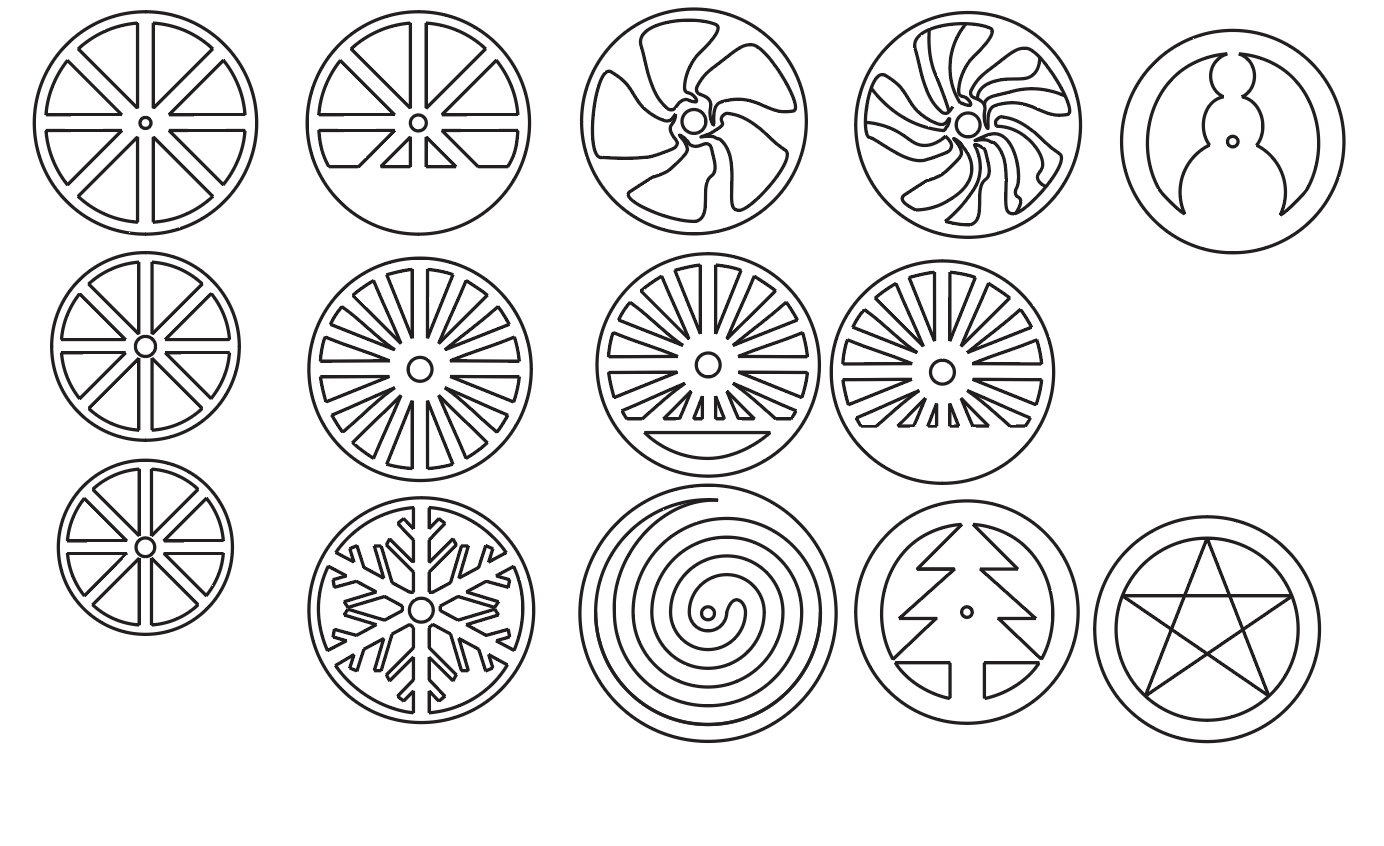

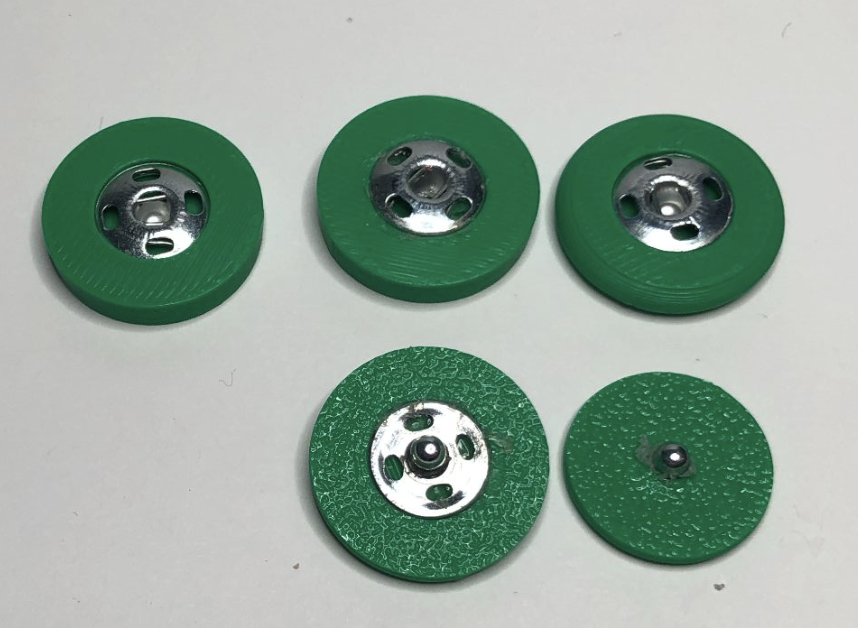

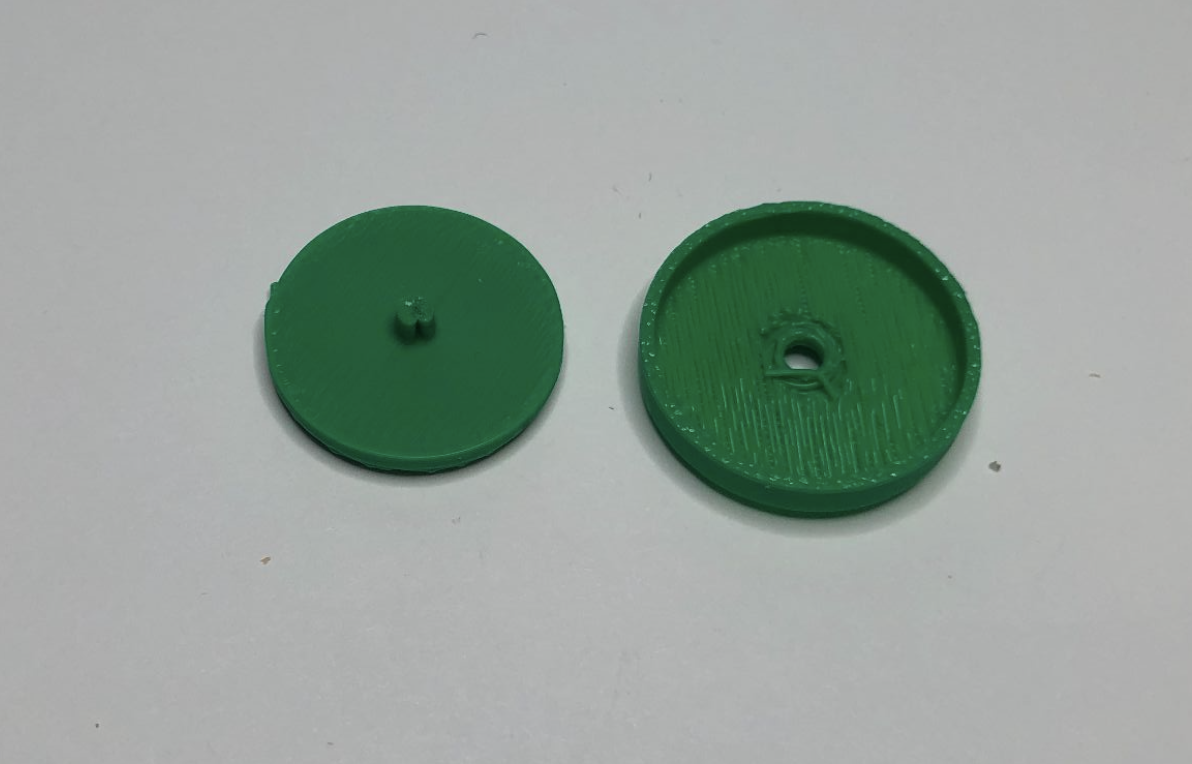

Wheel designs

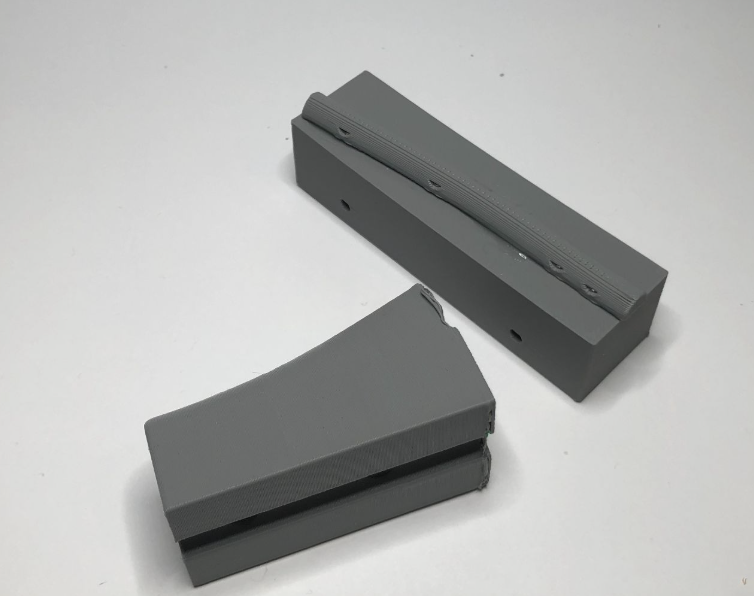

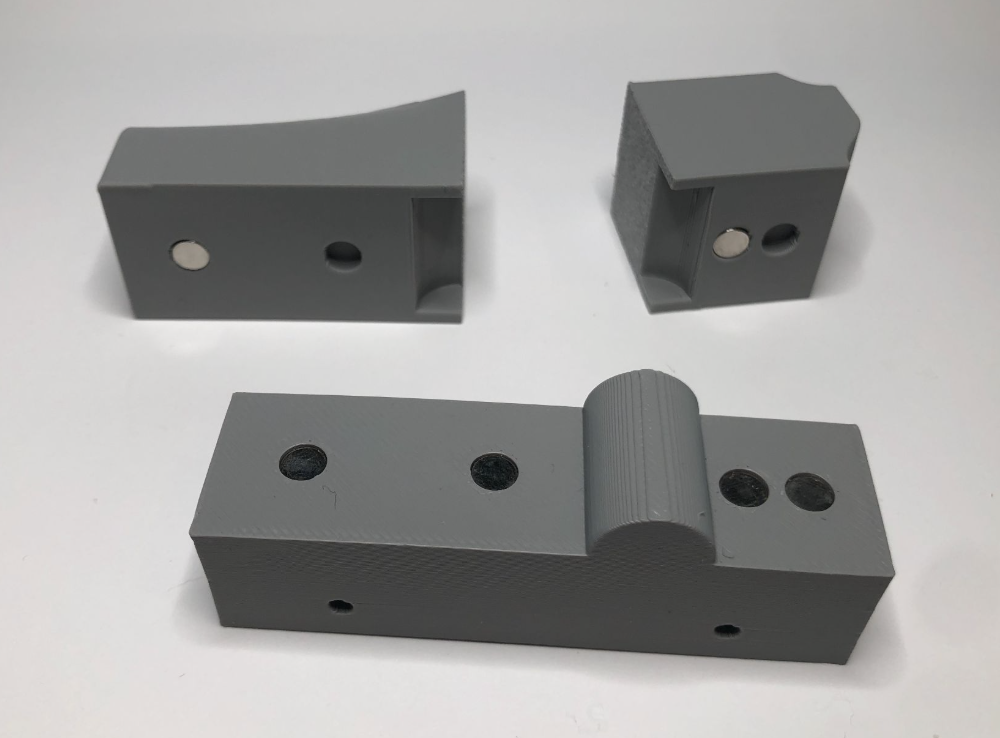

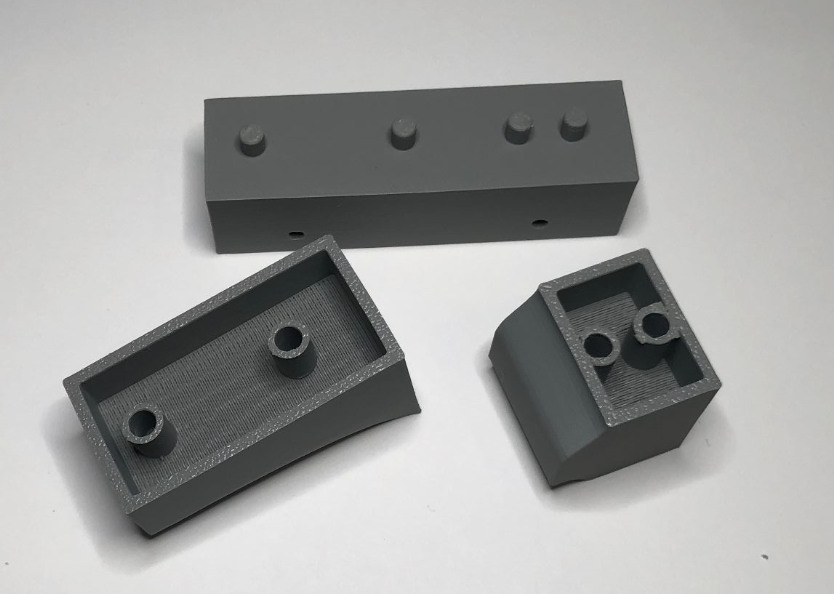

Initial Prototype

Small-Scale Manufacturing

Over the course of a week, with the help of the fine folks at the Arroyo Repertory Theater, I oversaw the production of components for over 55 wooden trains.

Every Train Was Unique

The children who attended all got to customize, paint, and take home their very own train

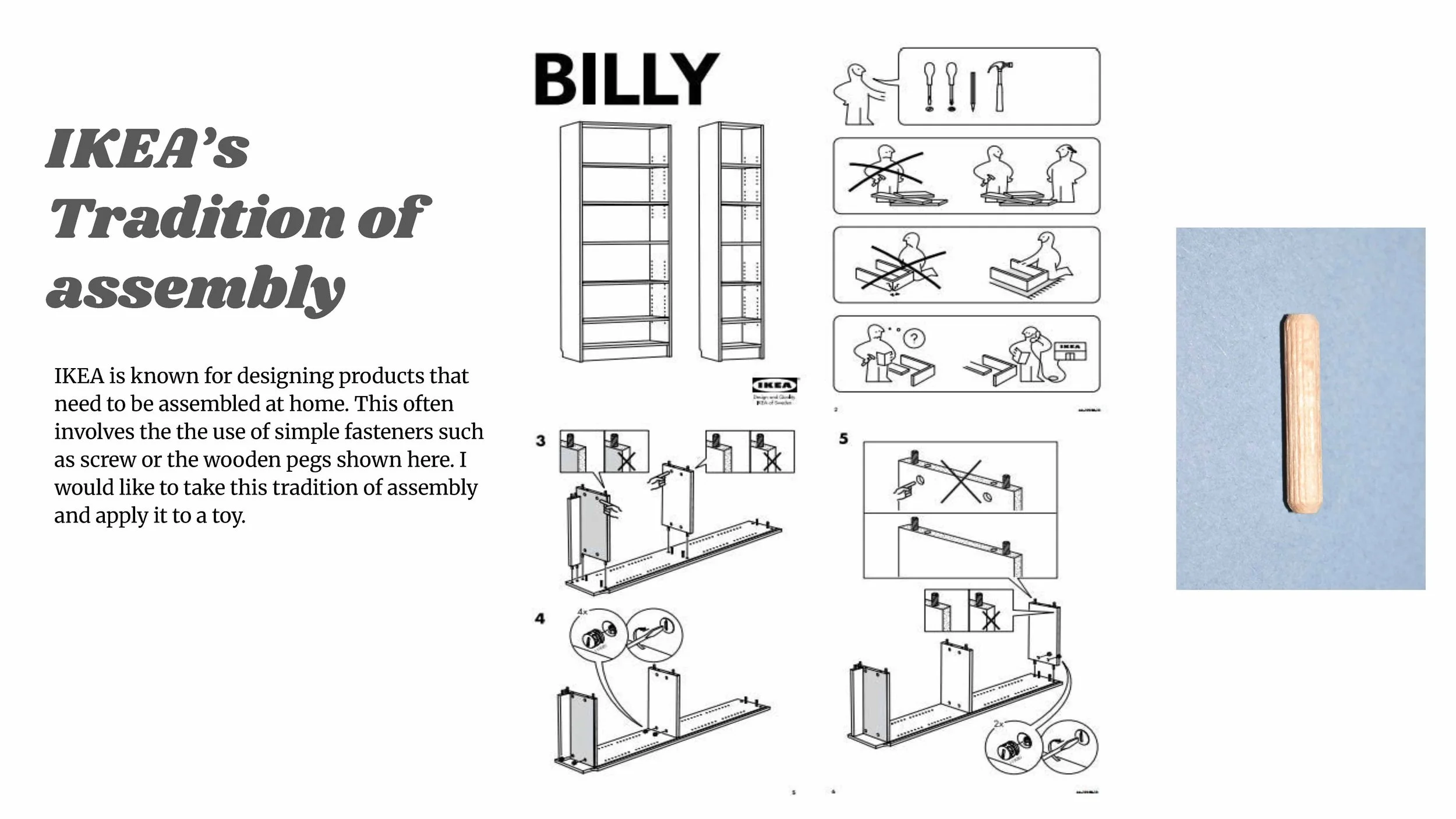

Assembly

Almost all of the parts fit together with wooden pegs and drilled holes. Even the axles were wooden dowels that were pressed into holes in the center of the wheels. The only parts that attached differently were the cow catchers (front attachments), which had to be glued on.

Enter: IKEA’s Lillabo Trains

For a 14-week-long class in the spring of 2025, I was prompted to design for IKEA. I chose to focus on Redesigning IKEA’s Lillabo train line. Lilllabo is Ikea’s in-house toy train brand. Unlike their competitors, IKEA seeks to emulate modern high-speed trains as opposed to classic steam trains.

Concept Development

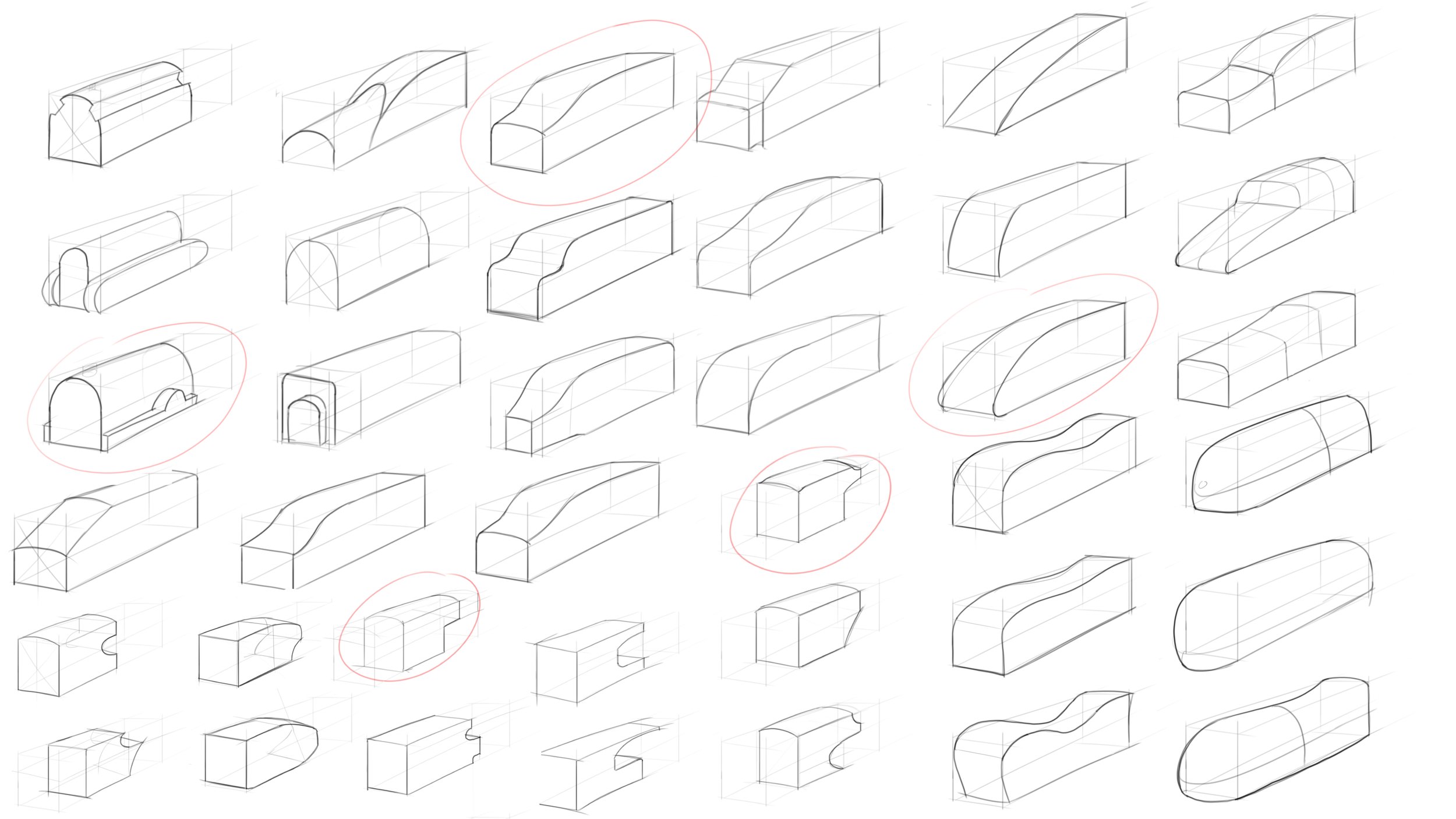

Form Development

Connector Ideation

Material Sourcing

In my research, I learned that wooden trains are usually made out of a hardwood called European beech. It was very important to me to use the actual material in this project, so I called several local lumberyards to try to find a piece of European beech in the appropriate size.

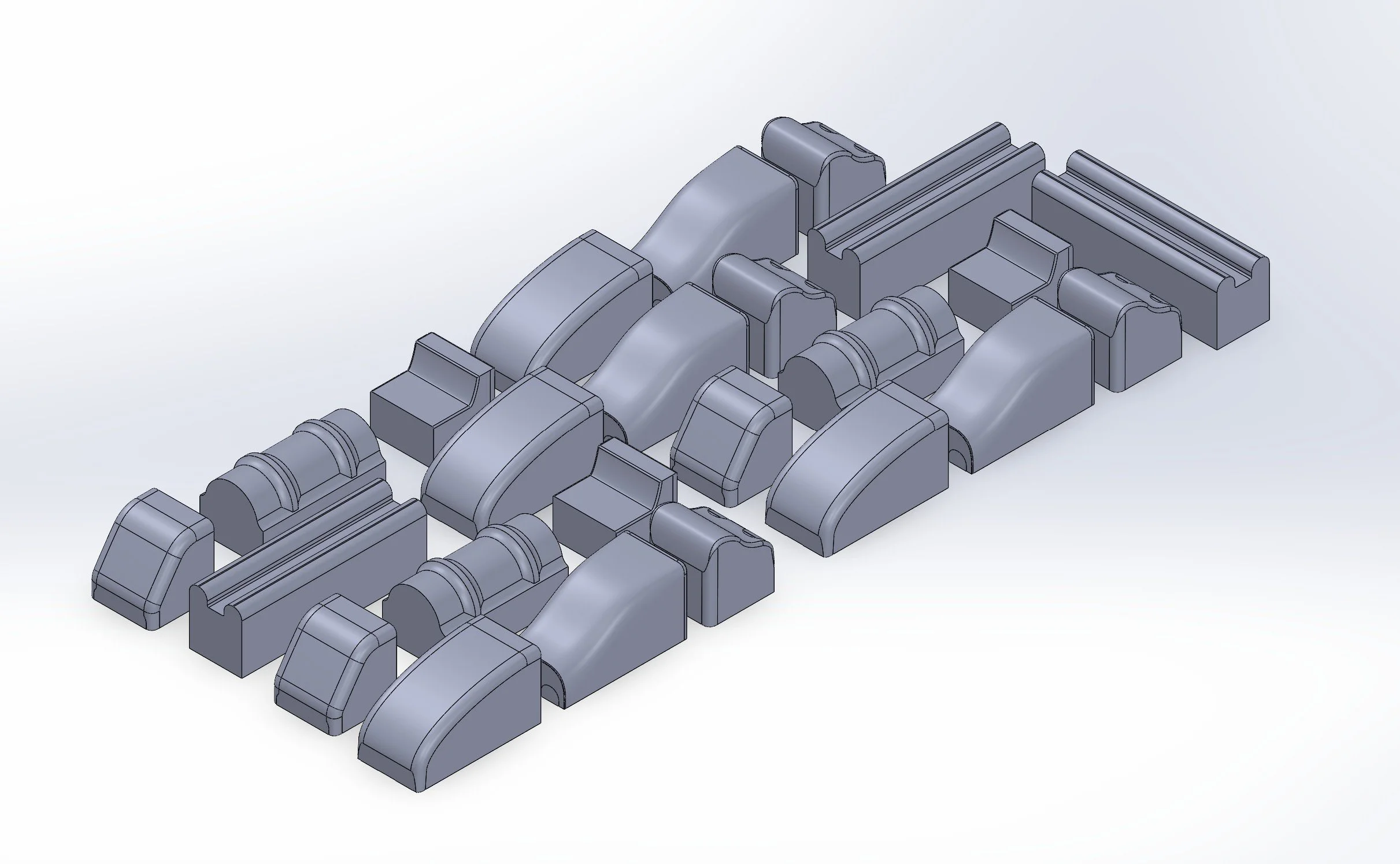

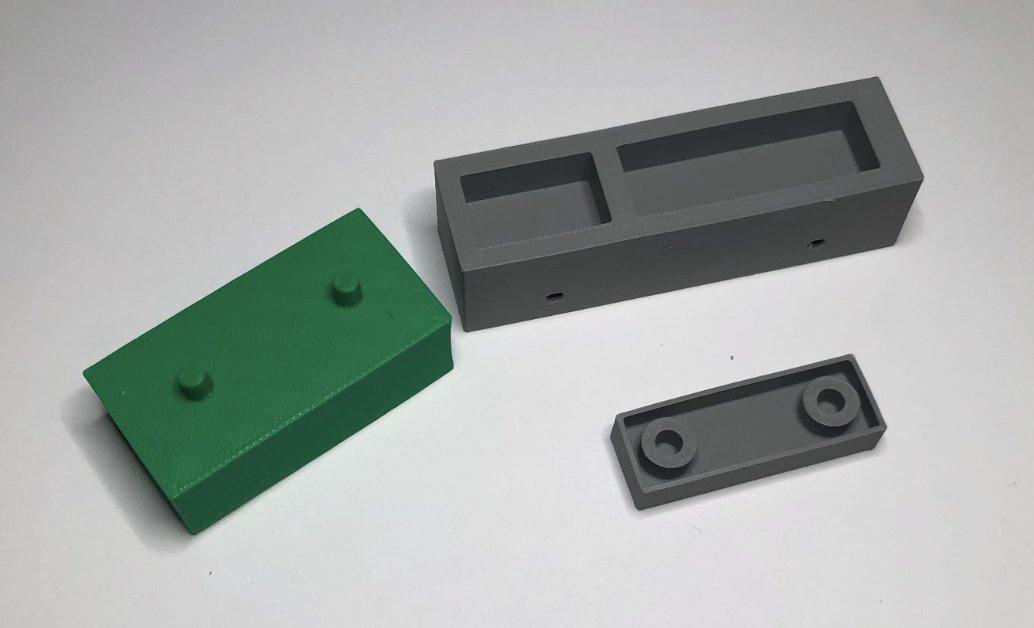

3D Modeling

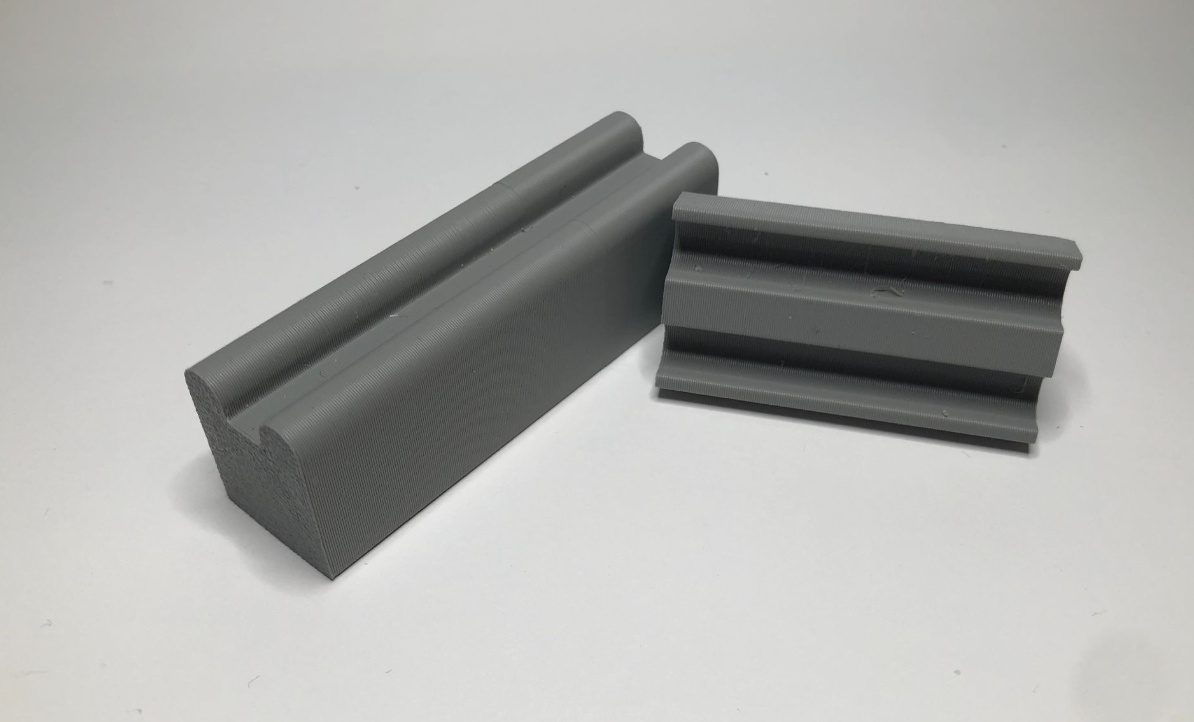

While working on this project, I was learning more advanced 3D modelling techniques in SolidWorks (such as surface boundary). This came in handy for creating some of the more organic shapes I needed. I had also planned on CNC milling the train bodies early on in the process, so while 3D modelling, I made sure undercuts were removed, and the maximum number of parts was fit in my material stock.