Miang Kham

Floating Lily Pad Dish

Design inspired by and makable in Thailand

Designed for a 14-week project at ArtCenter College of Design. This class included a two-week trip to Thailand, where we toured several ceramics manufacturing facilities. We then applied that knowledge to our designs and designed products that could be made in one of those factories. The skills I acquired are

3D modelling

Design for manufacturing

Slipcasting

Slump molding

Slab building

Drawing from field inspiration

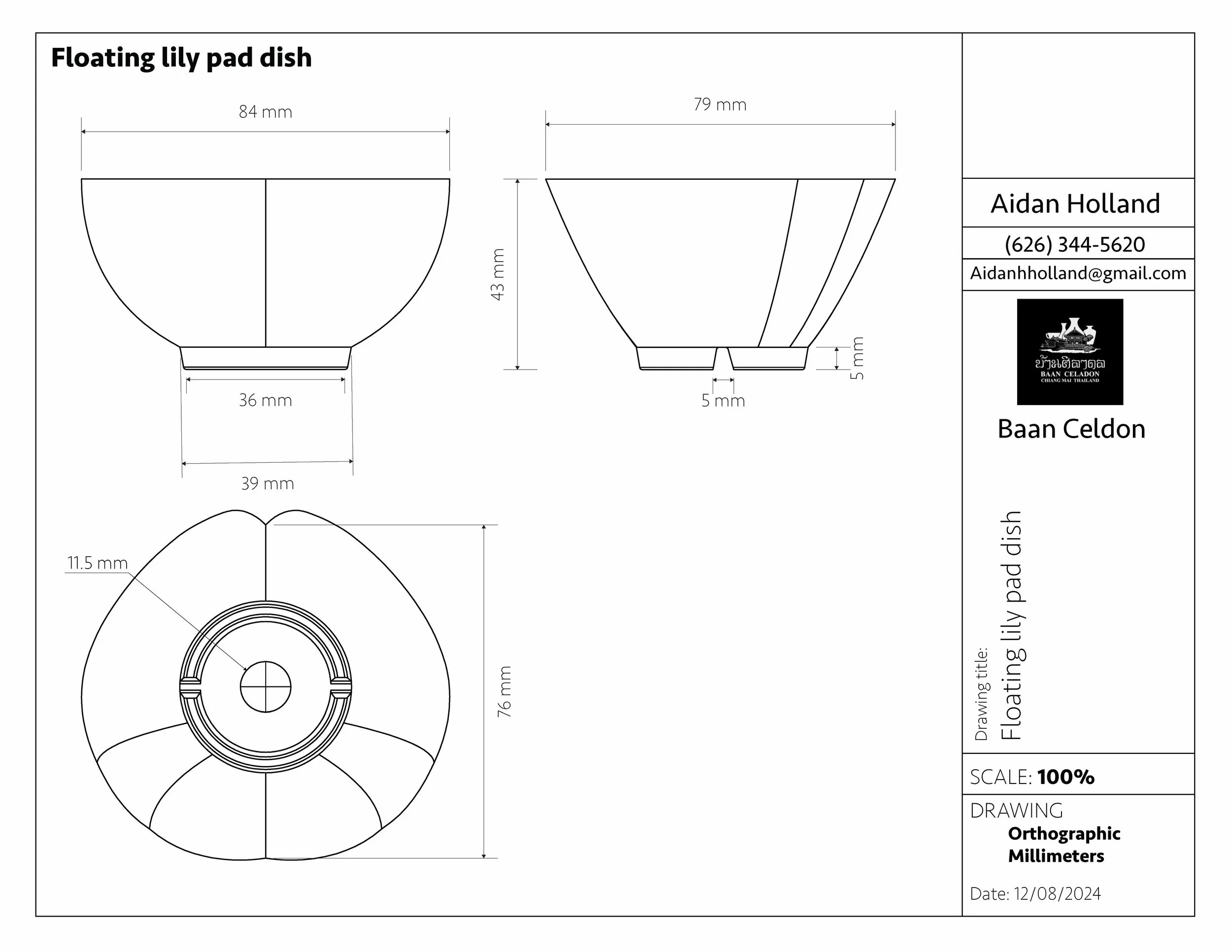

Technical drawing

Tech Pack development

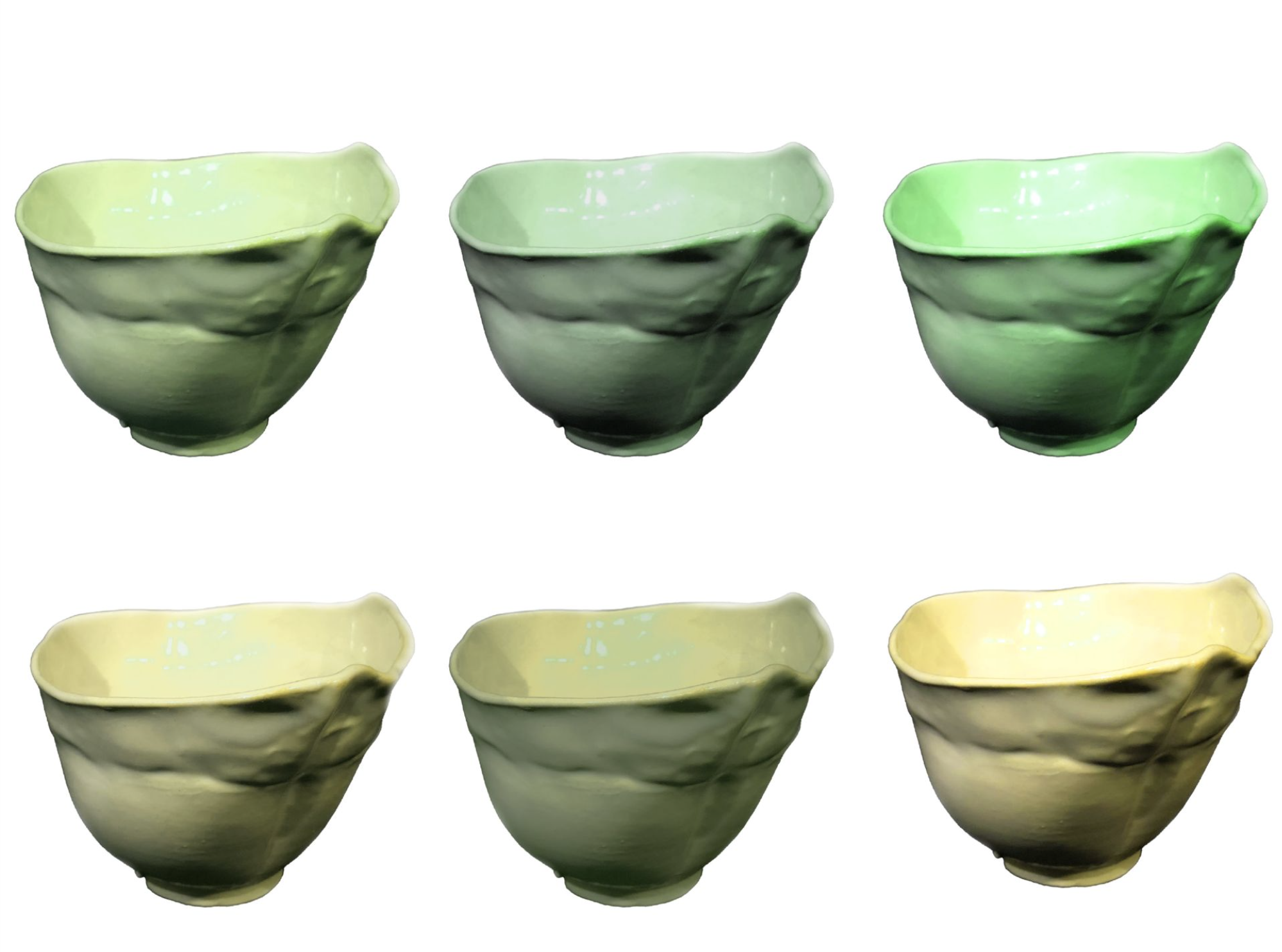

Glaze testing

Designing while travelling

It started with a trip to Thailand

And a curiosity at a gas station

where I purchased a floating ceramic fish toy for roughly 50 cents.

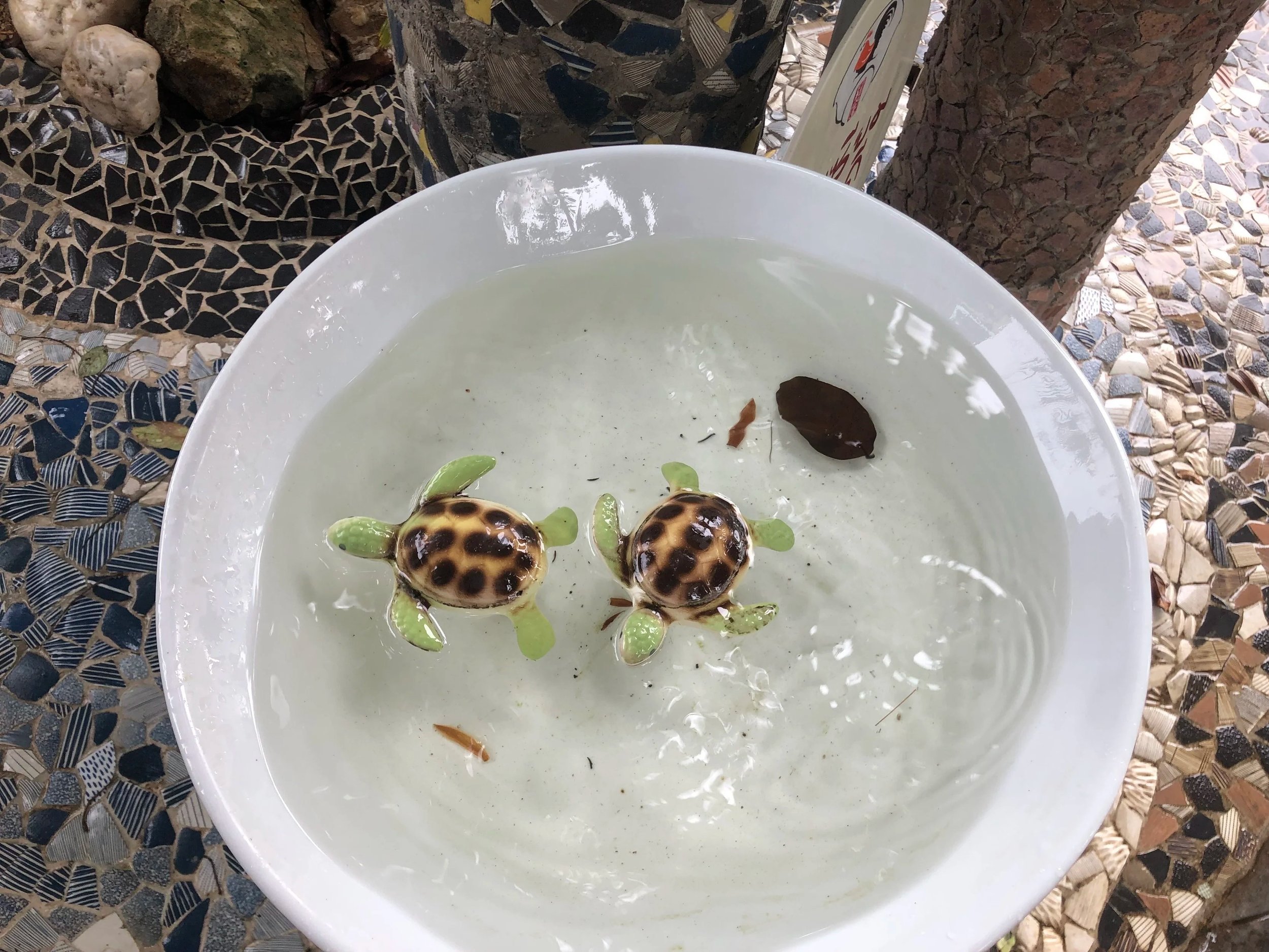

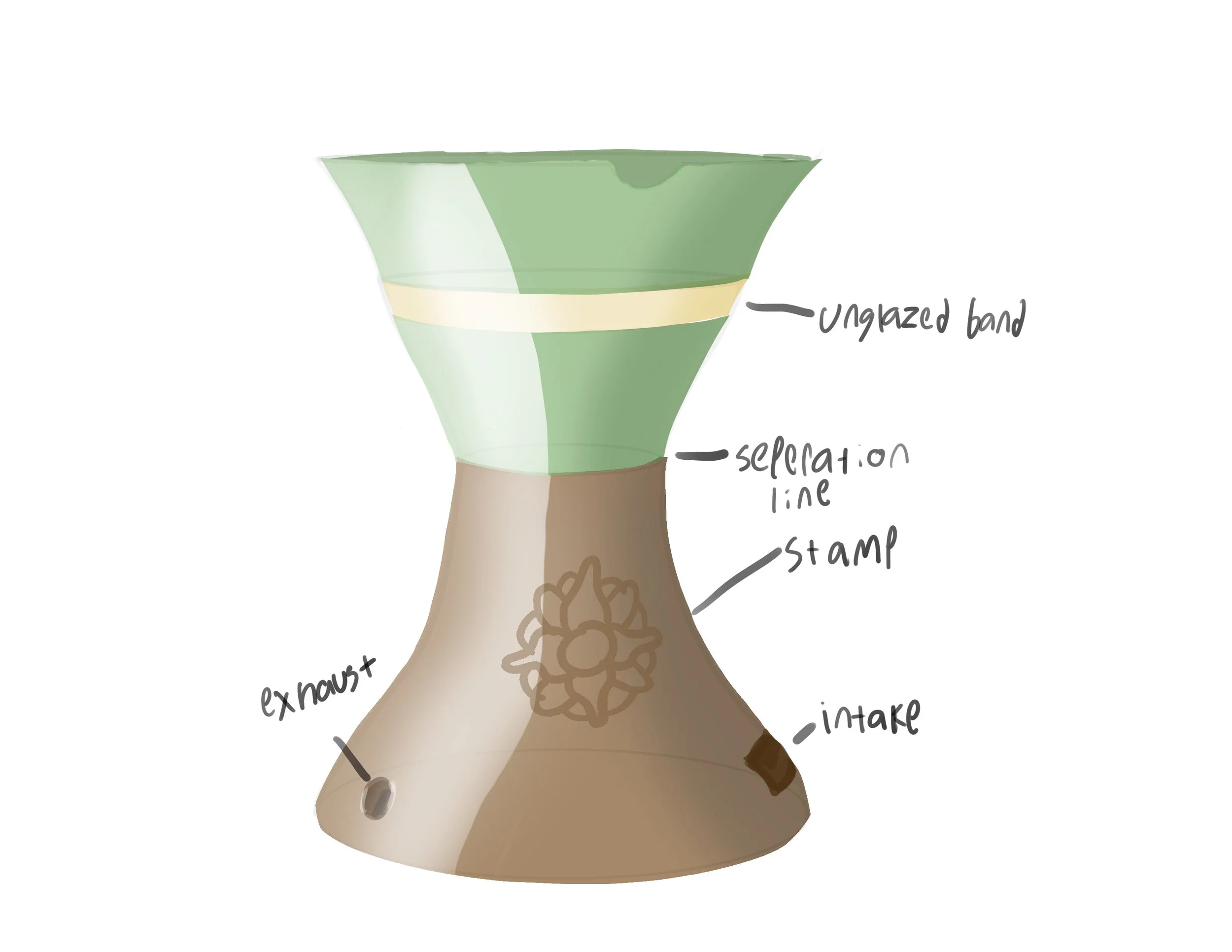

Floating Ceramics

I first discovered floating ceramics in a bird bath outside the Dhanabadee Ceramic Museum in Lampang. I had never seen floating ceramic before and was fascinated by the concept. Later that day, I found these very same toys for sale at that gas station and quickly purchased one.

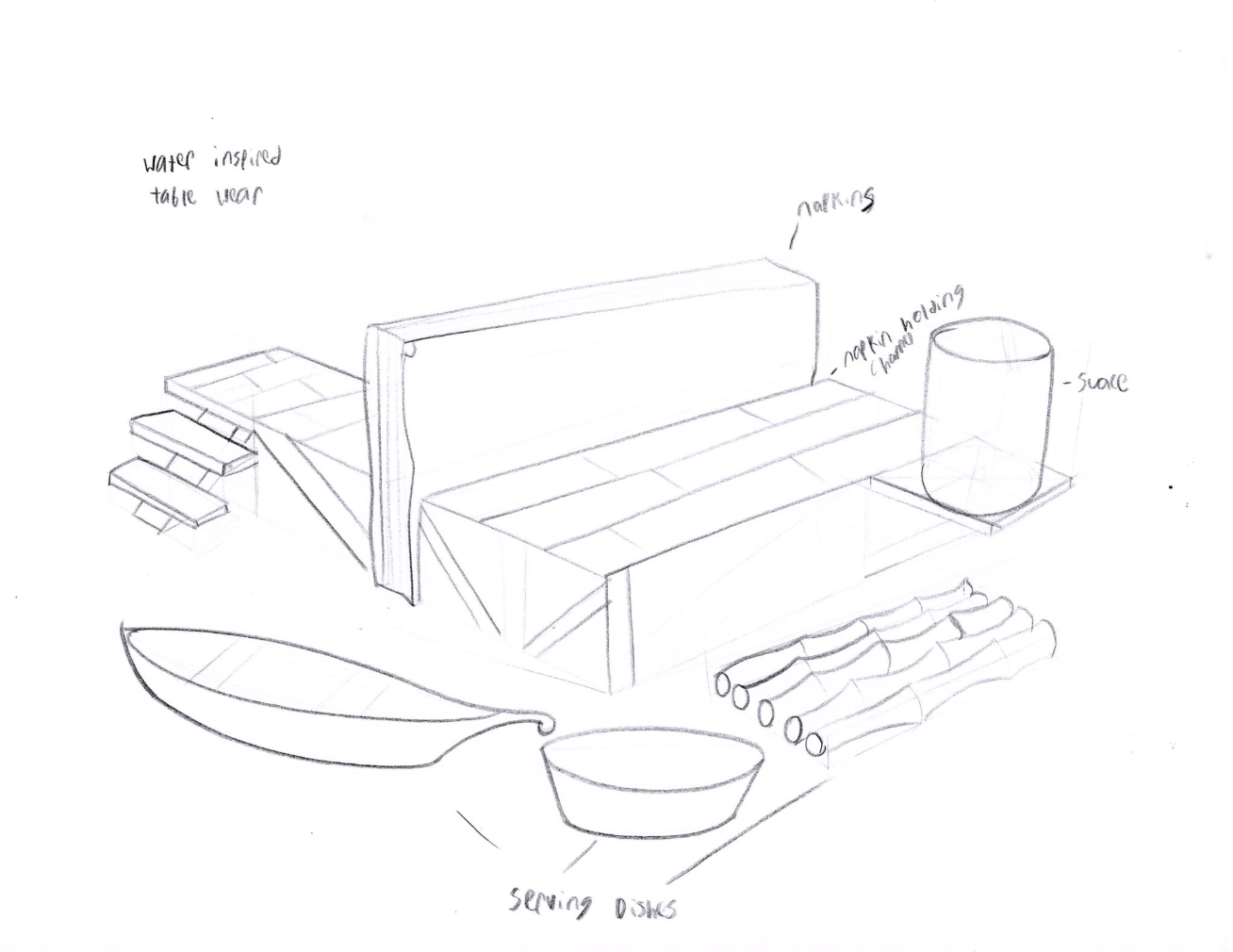

Suan Thip

A few days before my encounter with the ceramic fish, my group and I had the privilege of dining at a Michelin-star restaurant in Bangkok called Suan Thip. There, I tasted my favorite Thai dish for the first time: Miang Kham.

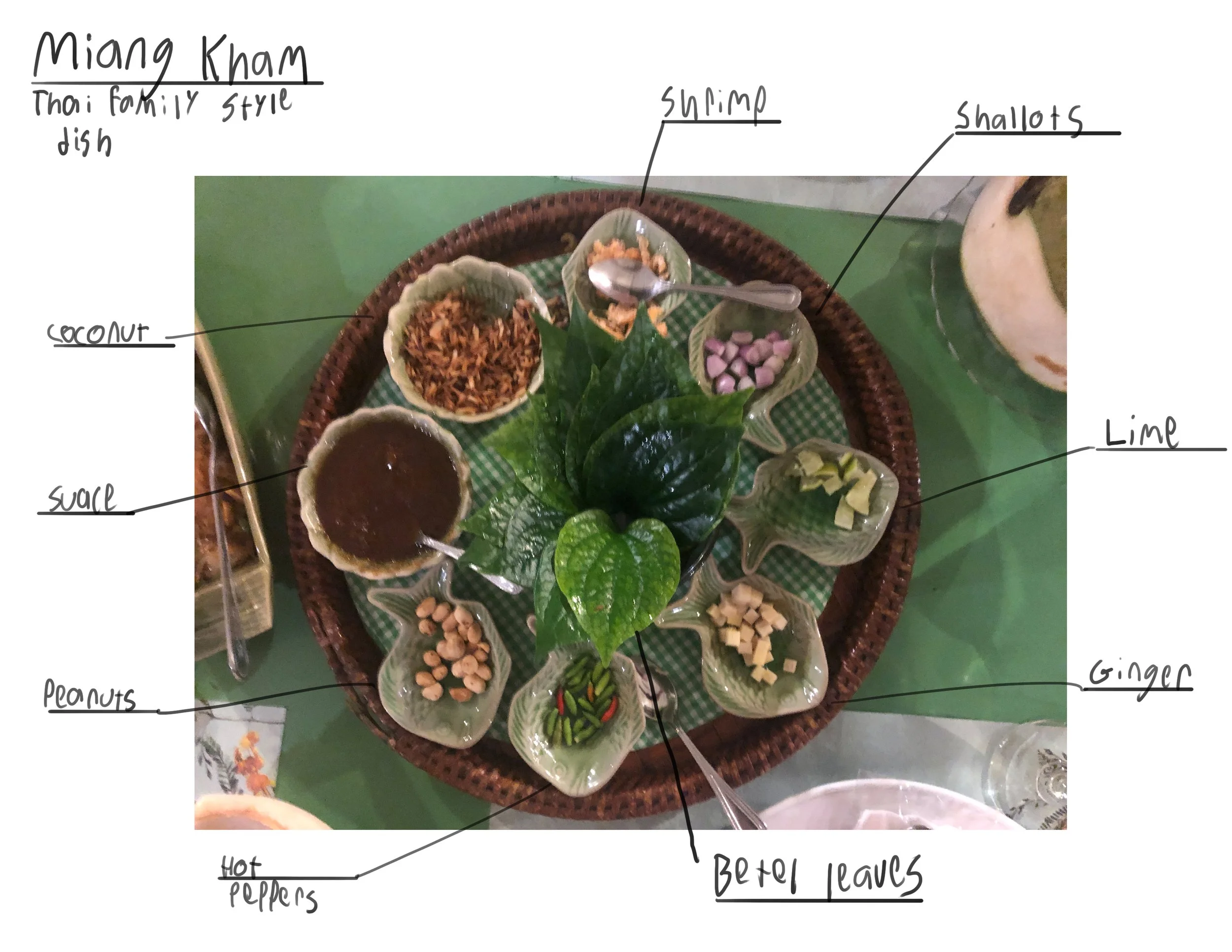

Miang Kham

This is a dish that is eaten by filling up a leaf with as much as you want of the several surrounding fillings (chopped shallots, bird’s eye chili peppers, ginger, garlic, lime, peanuts, small dried shrimp, and a sauce)

Lily Pads

While at a ceramic studio called Celepot, in Chiang Mai, I came face to face with some wonderful lily pads. These aquatic plants were huge and looked sturdy enough to stand on. This inspired me to float ceramic lily pad dishes to serve Miang Kham on.

Water Abundance

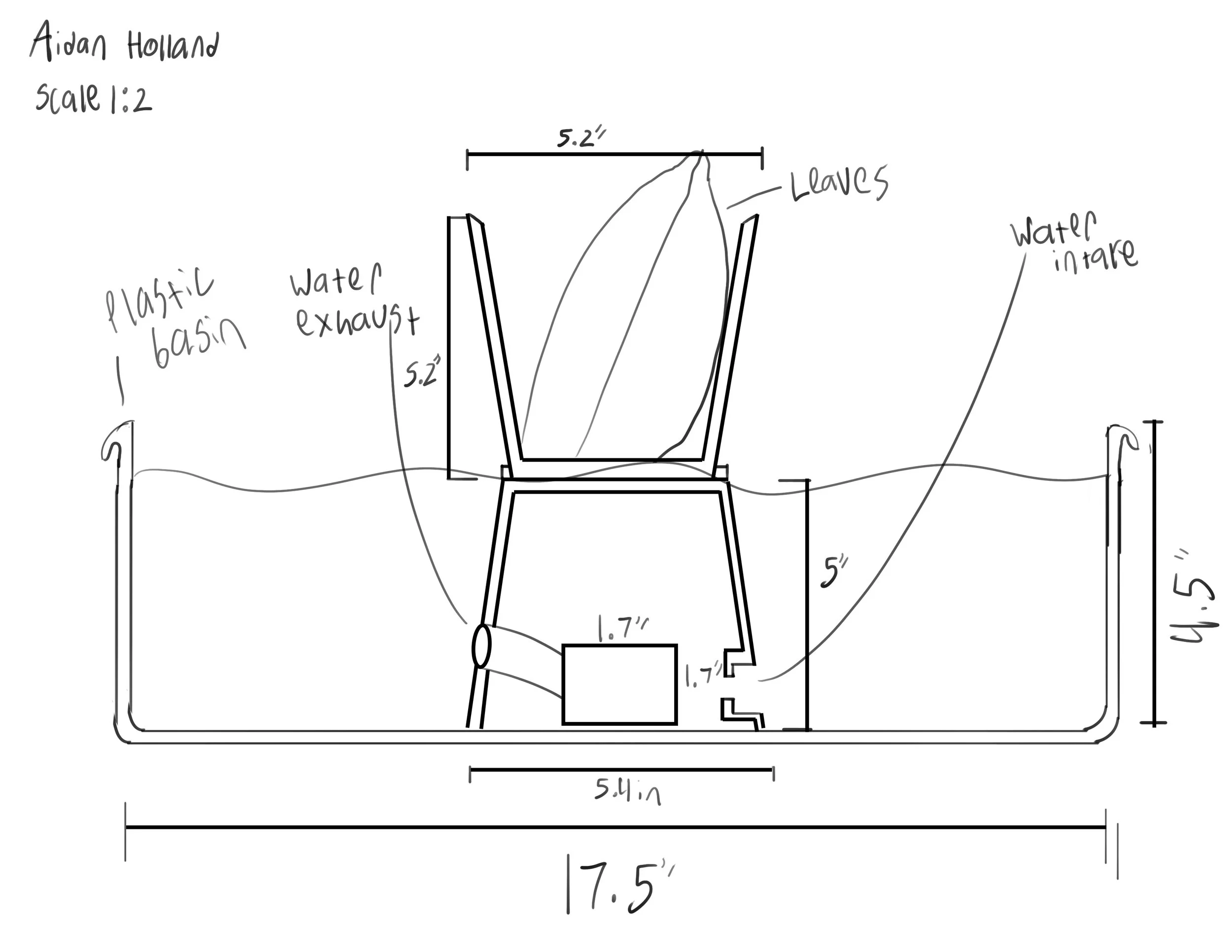

One of the most striking things I noticed in Thailand was the abundance of water. I grew up in Southern California, so I am used to water being very scarce, and I was blown away by how different an experience of water the Thai people had. This inspired me to focus on incorporating water into my project. This led me to create a circulating water basin to put my floating dishes in.

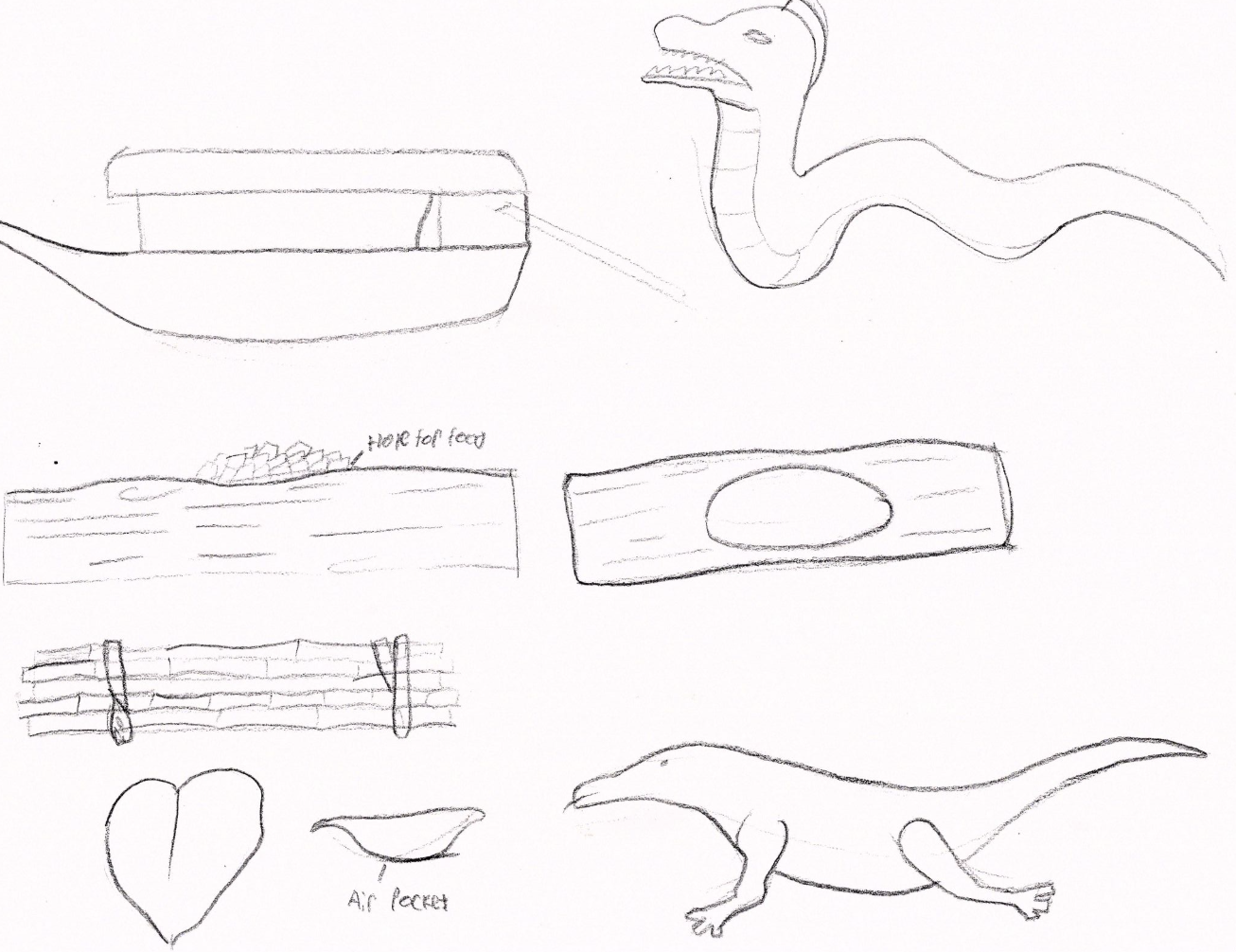

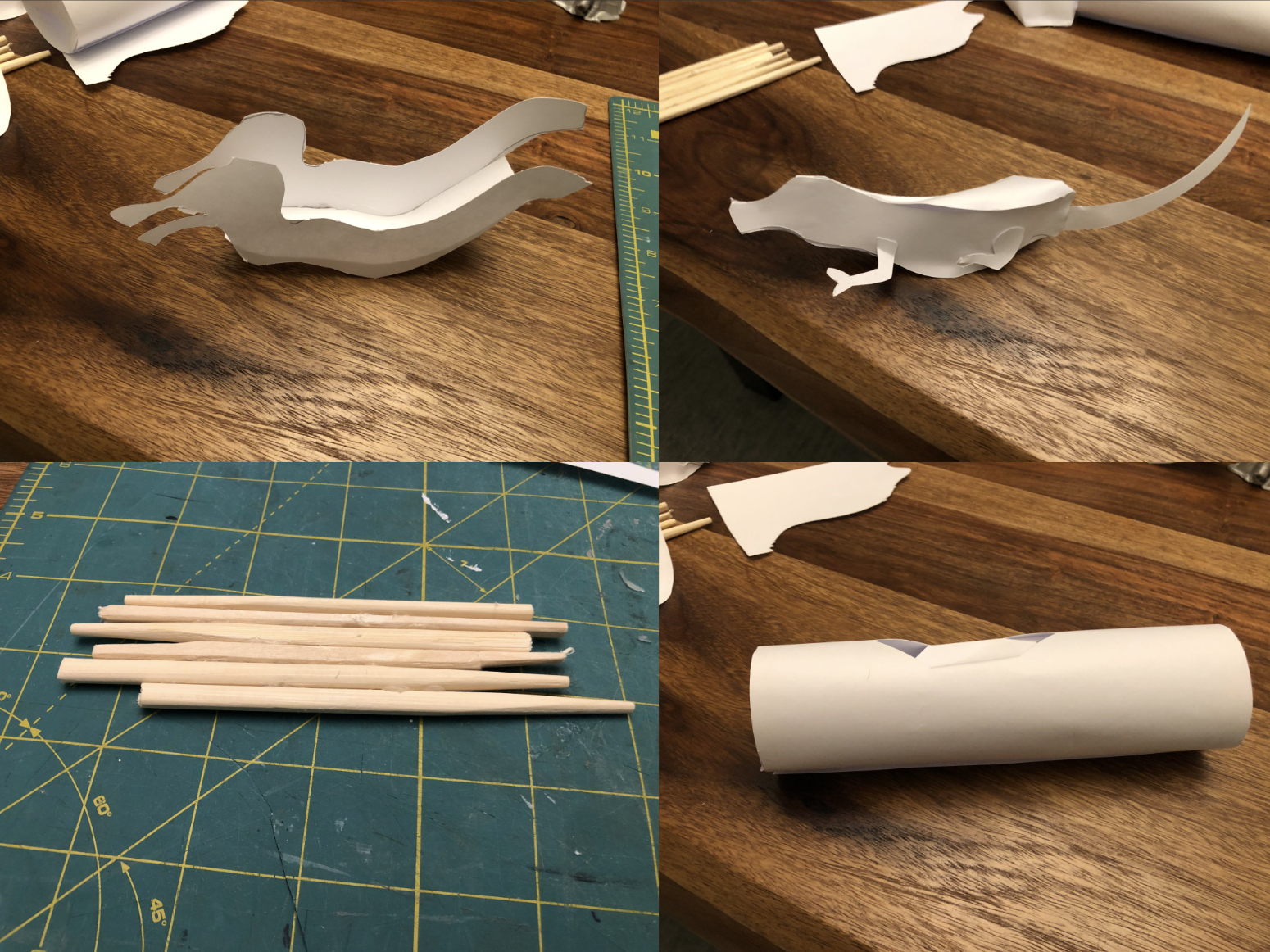

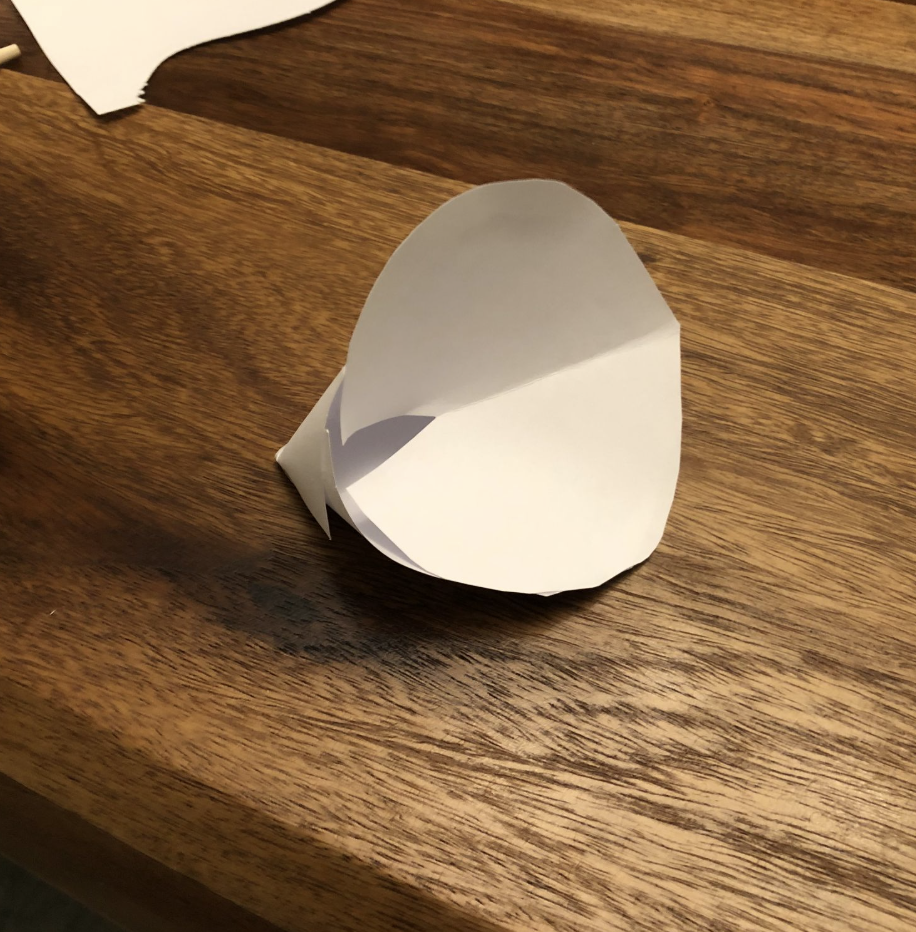

Mastering Flotation

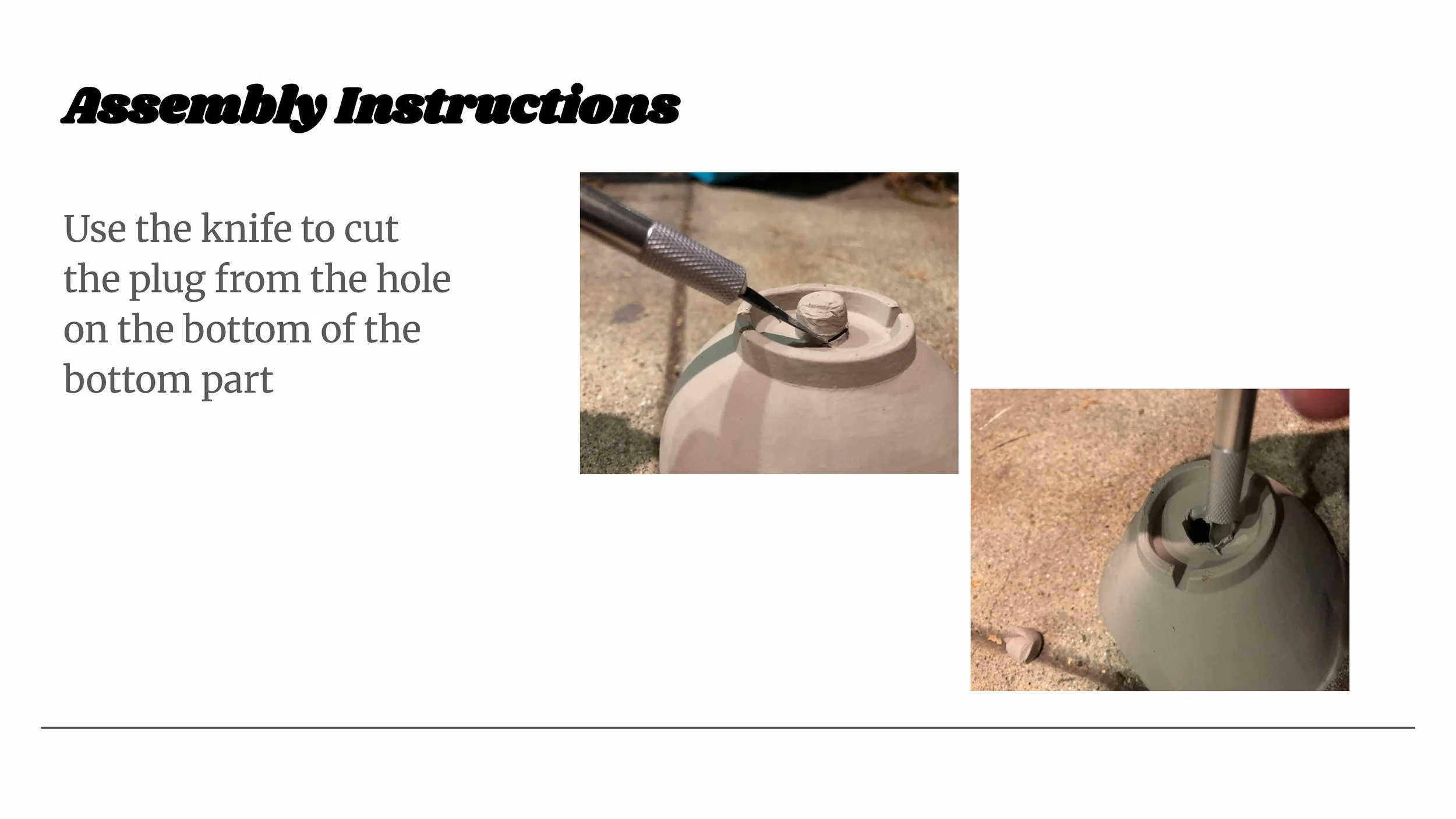

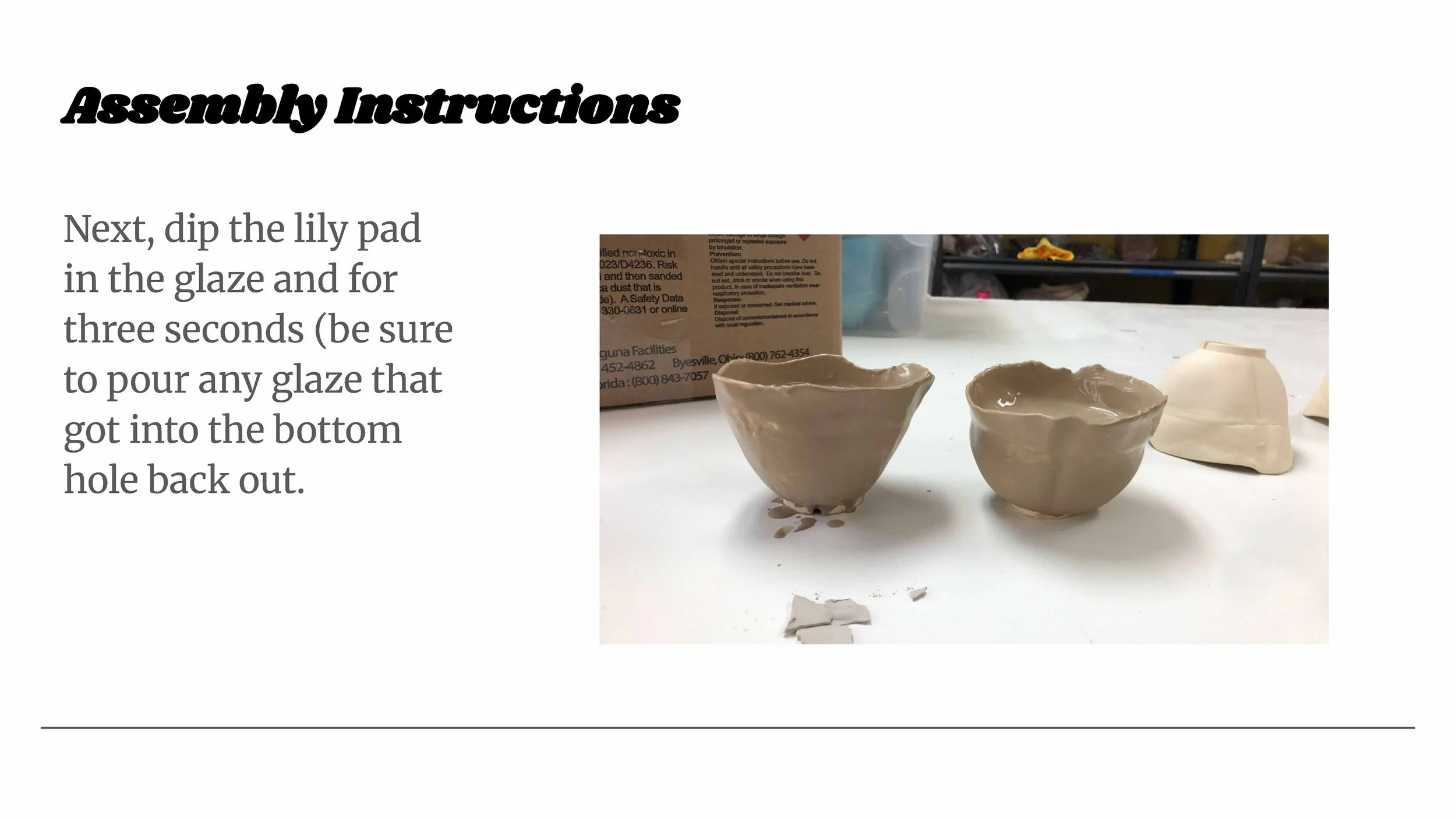

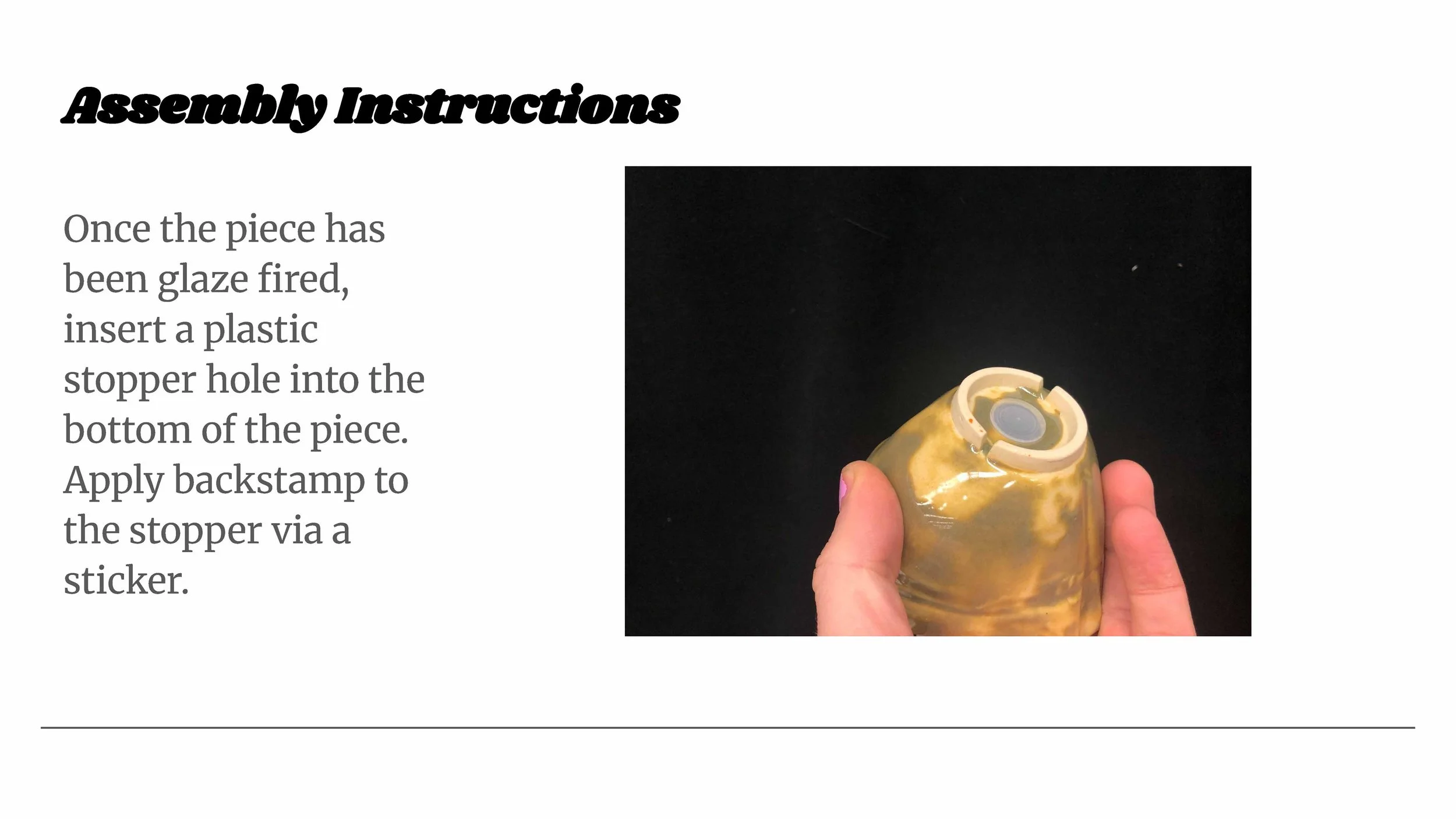

Once I was back in California, I got to work figuring out how to create

an air pocket within the clay to allow the lily pad dish to float

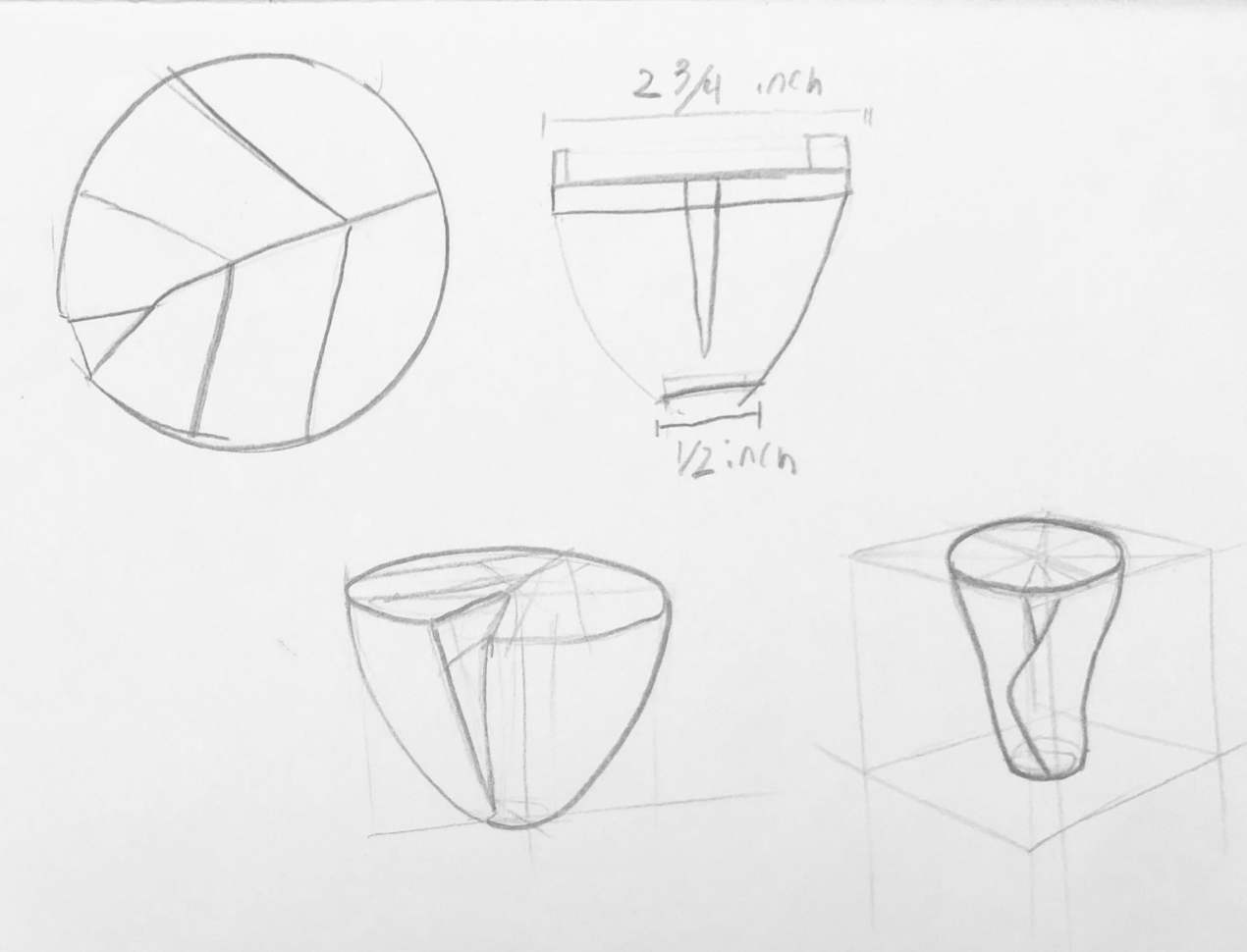

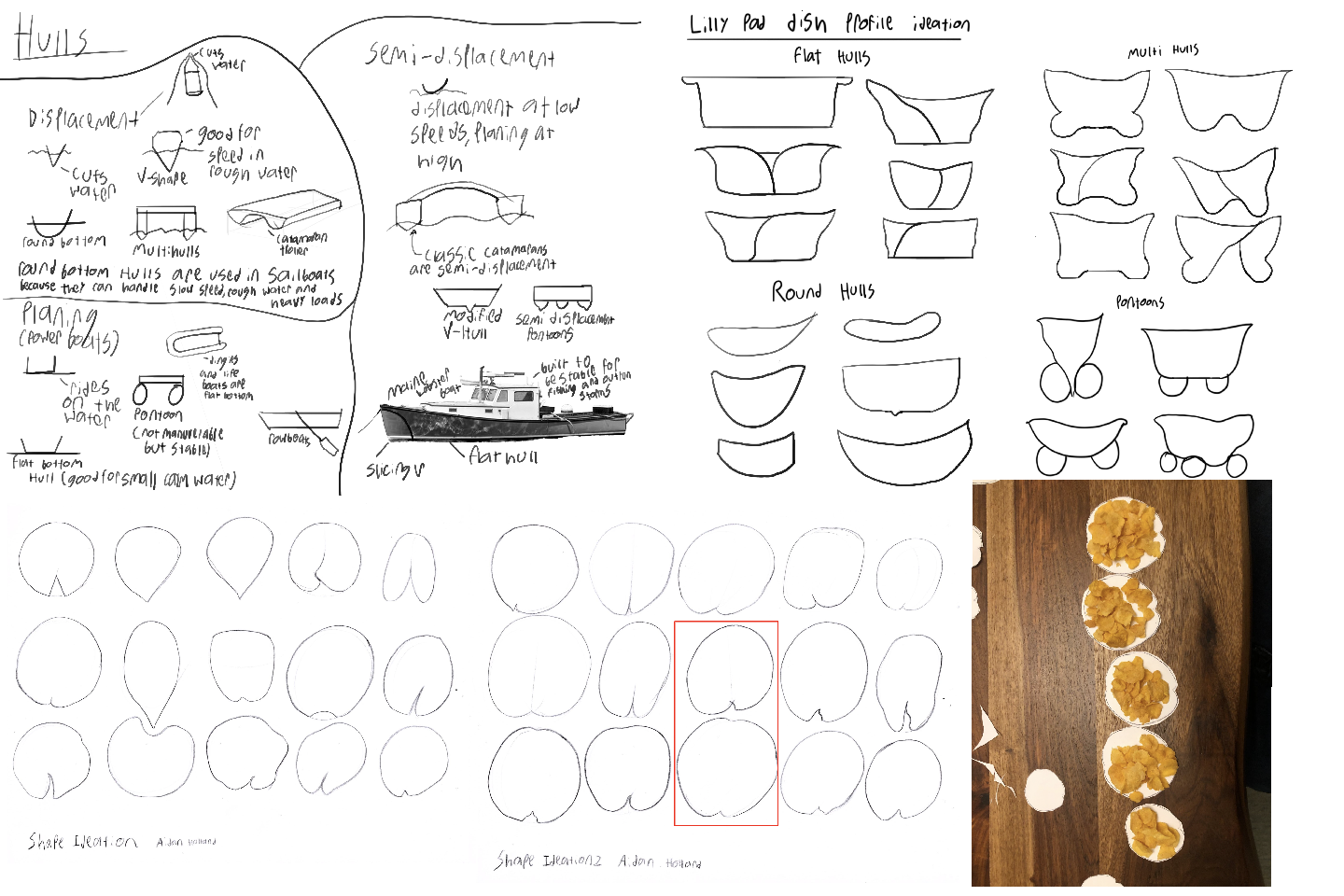

Form and Size Development

Almost all of the parts fit together with wooden pegs and drilled holes. Even the axles were wooden dowels that were pressed into holes in the center of the wheels. The only parts that attached differently were the cow catchers (front attachments), which had to be glued on.

3D Form Development

While working on this project, I was learning more advanced 3D modelling techniques in SolidWorks (such as surface boundary). This came in handy for creating some of the more organic shapes I needed. I had also planned on CNC milling the train bodies early on in the process, so while 3D modelling, I made sure undercuts were removed, and the maximum number of parts was fit in my material stock.

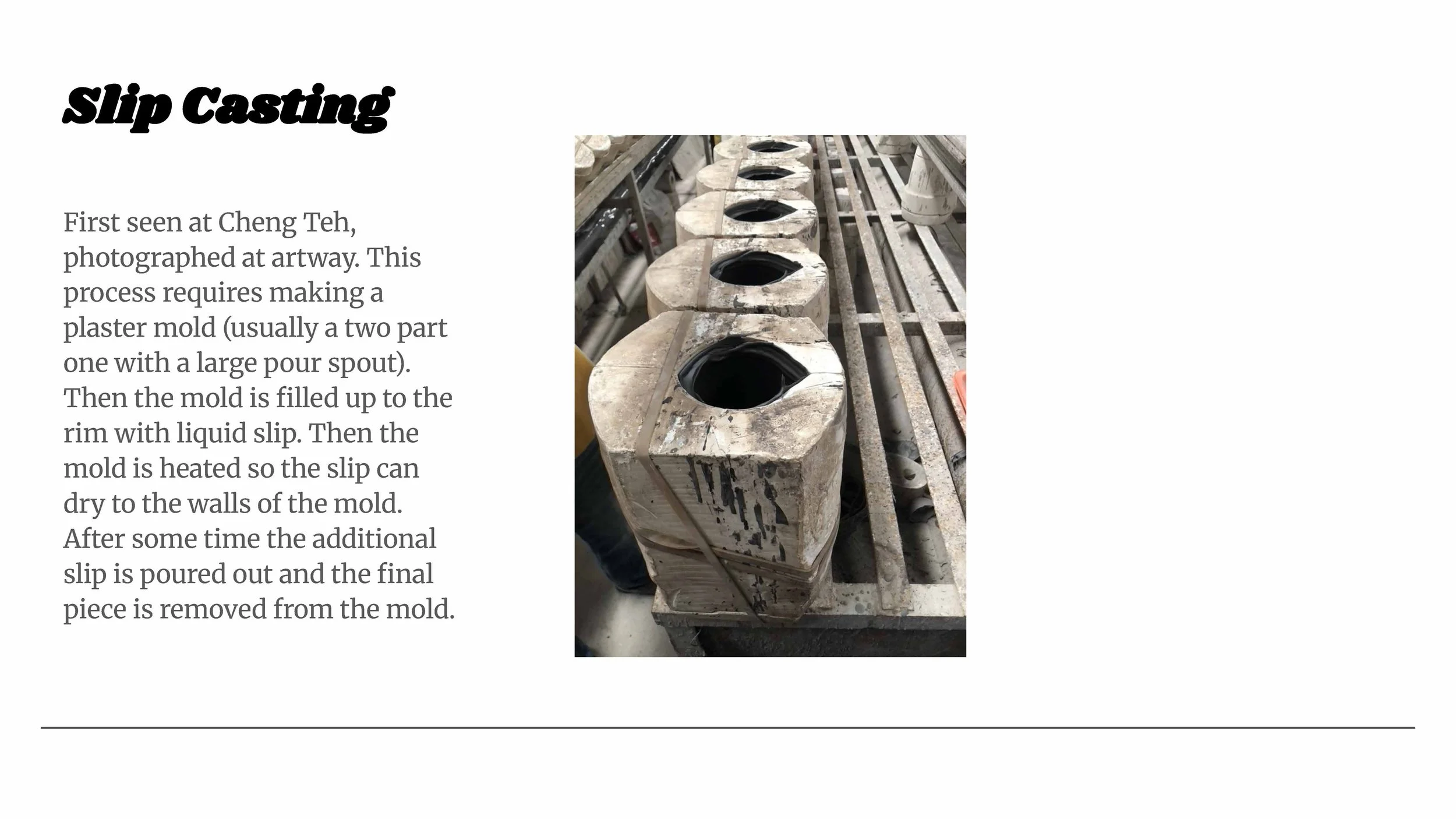

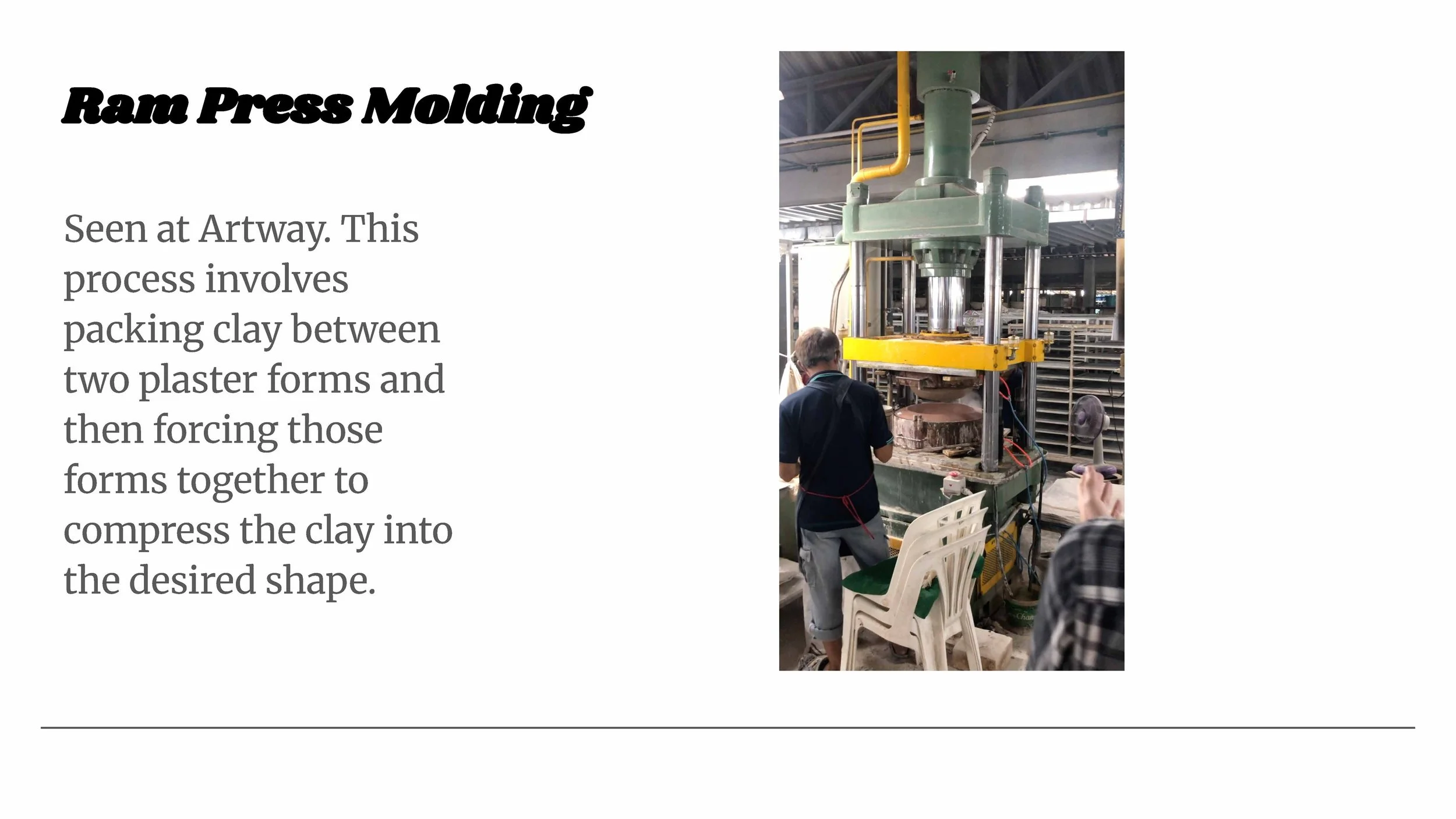

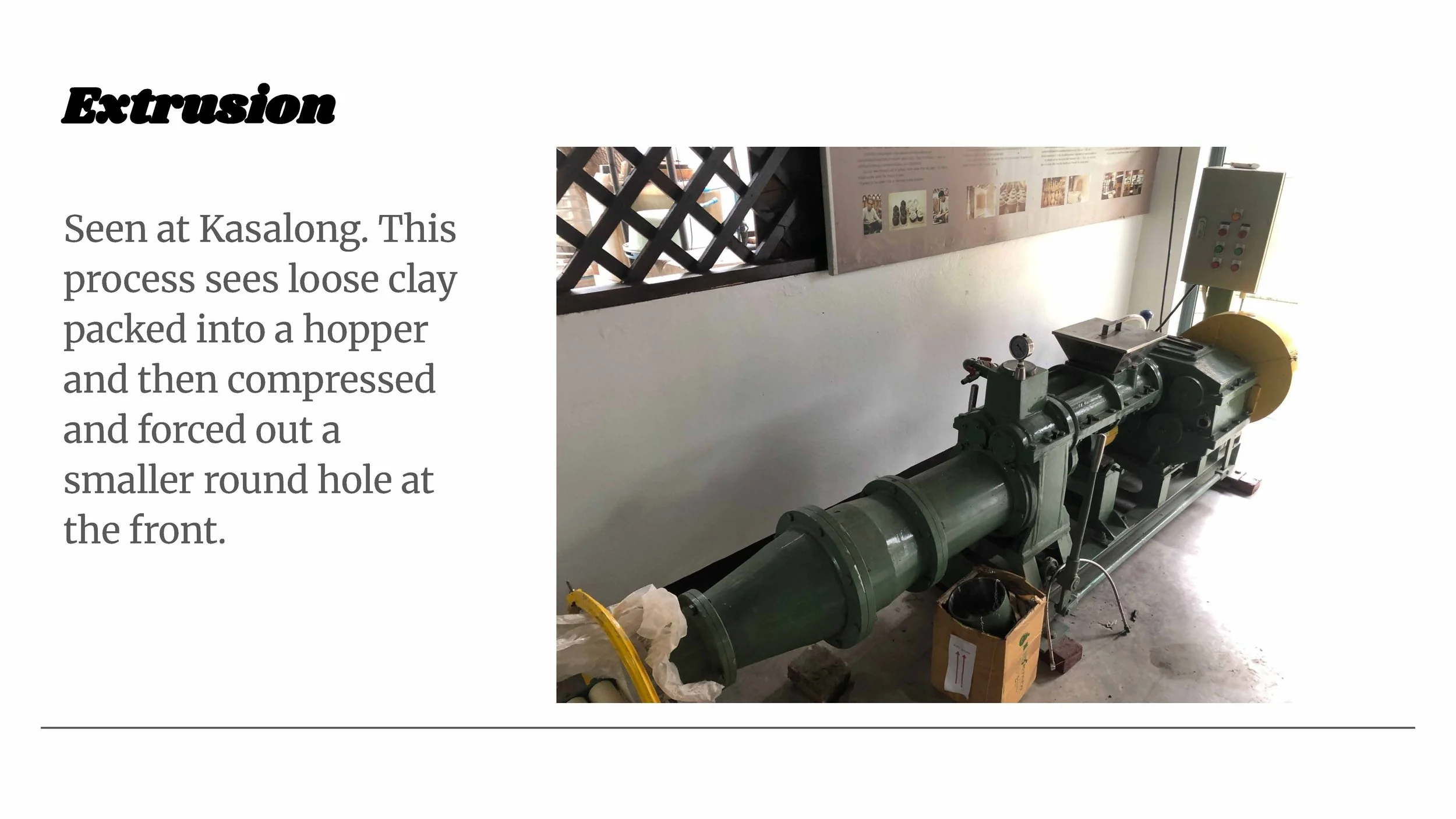

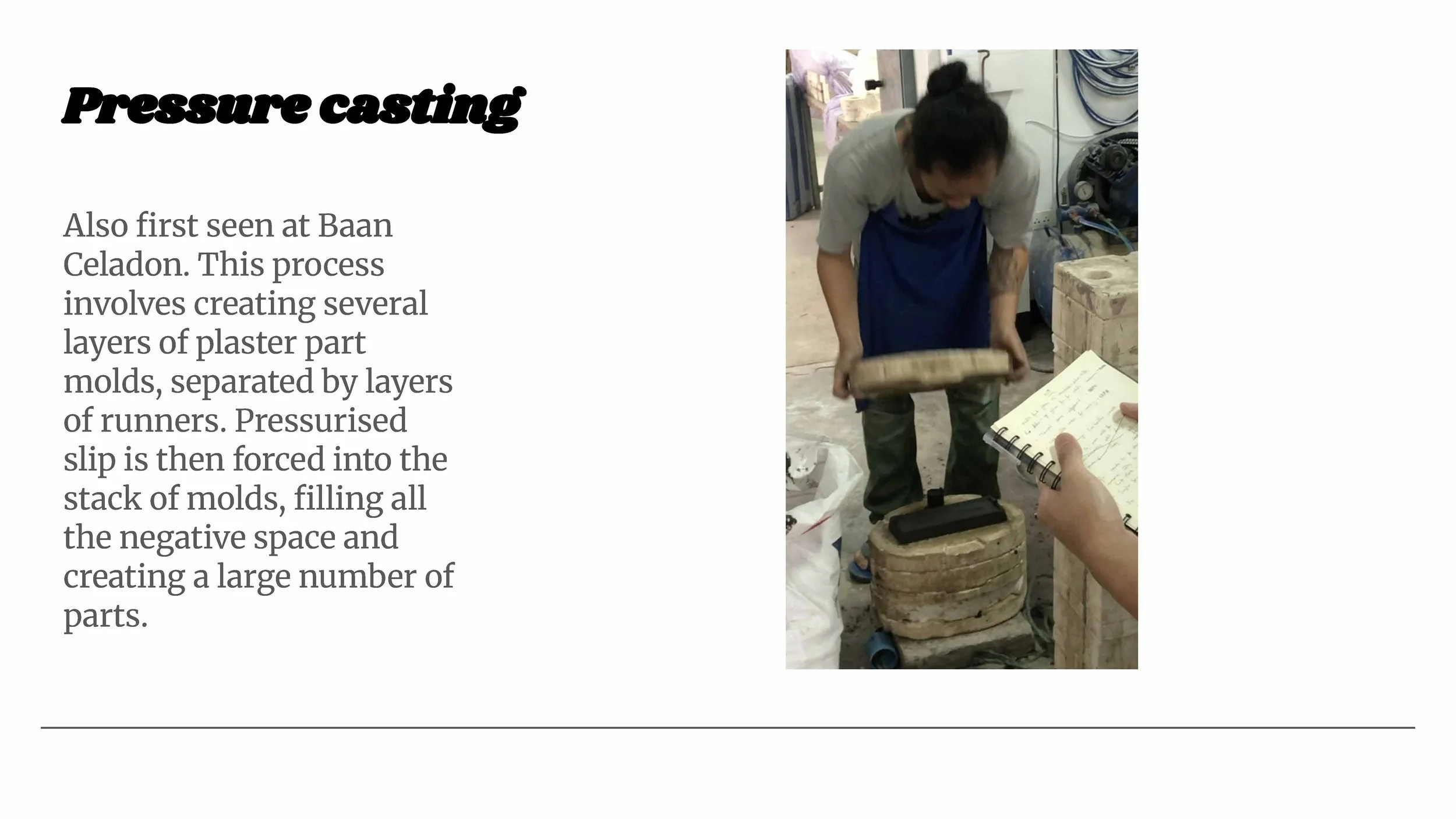

Manufaturing in Thailand

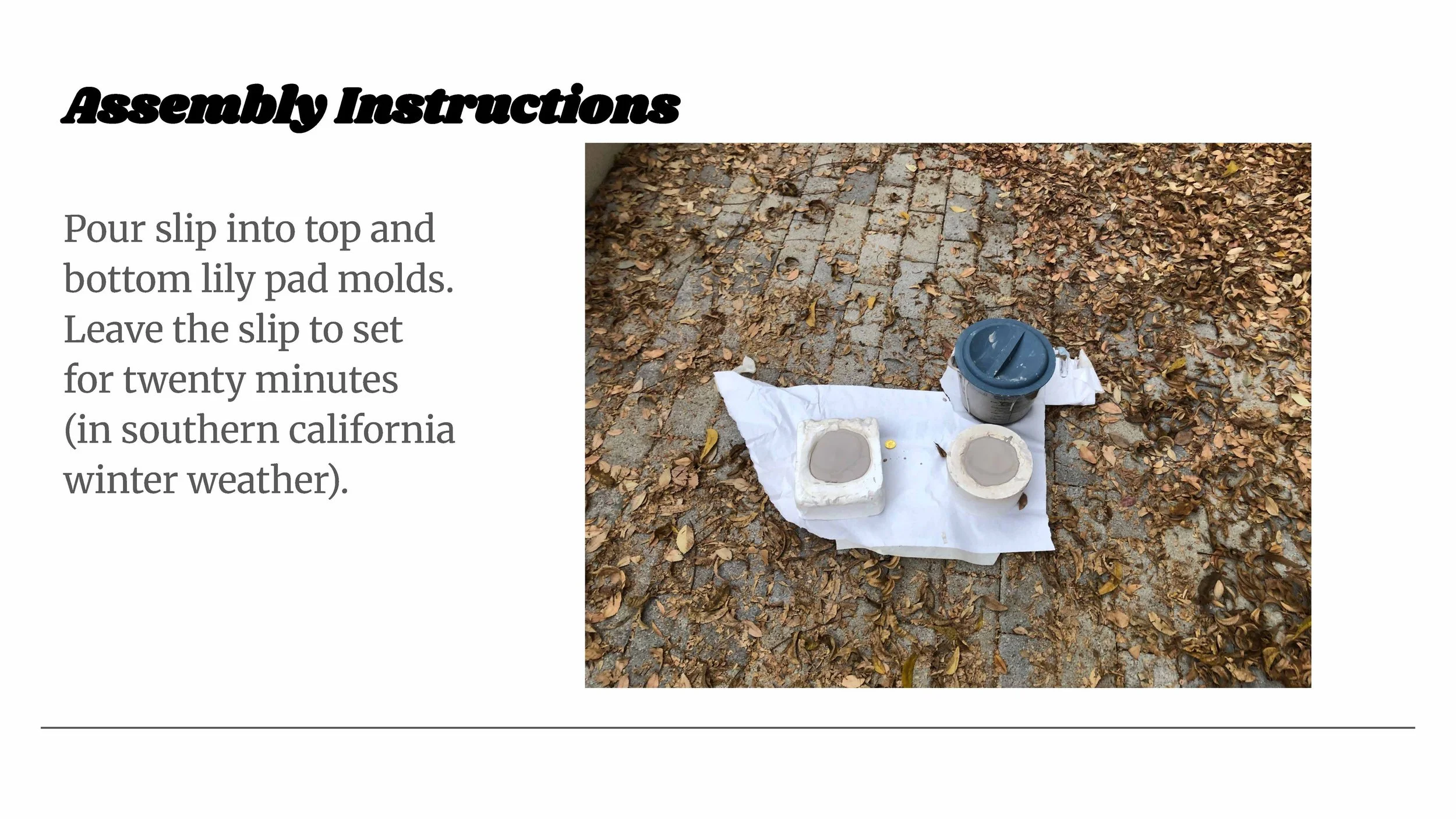

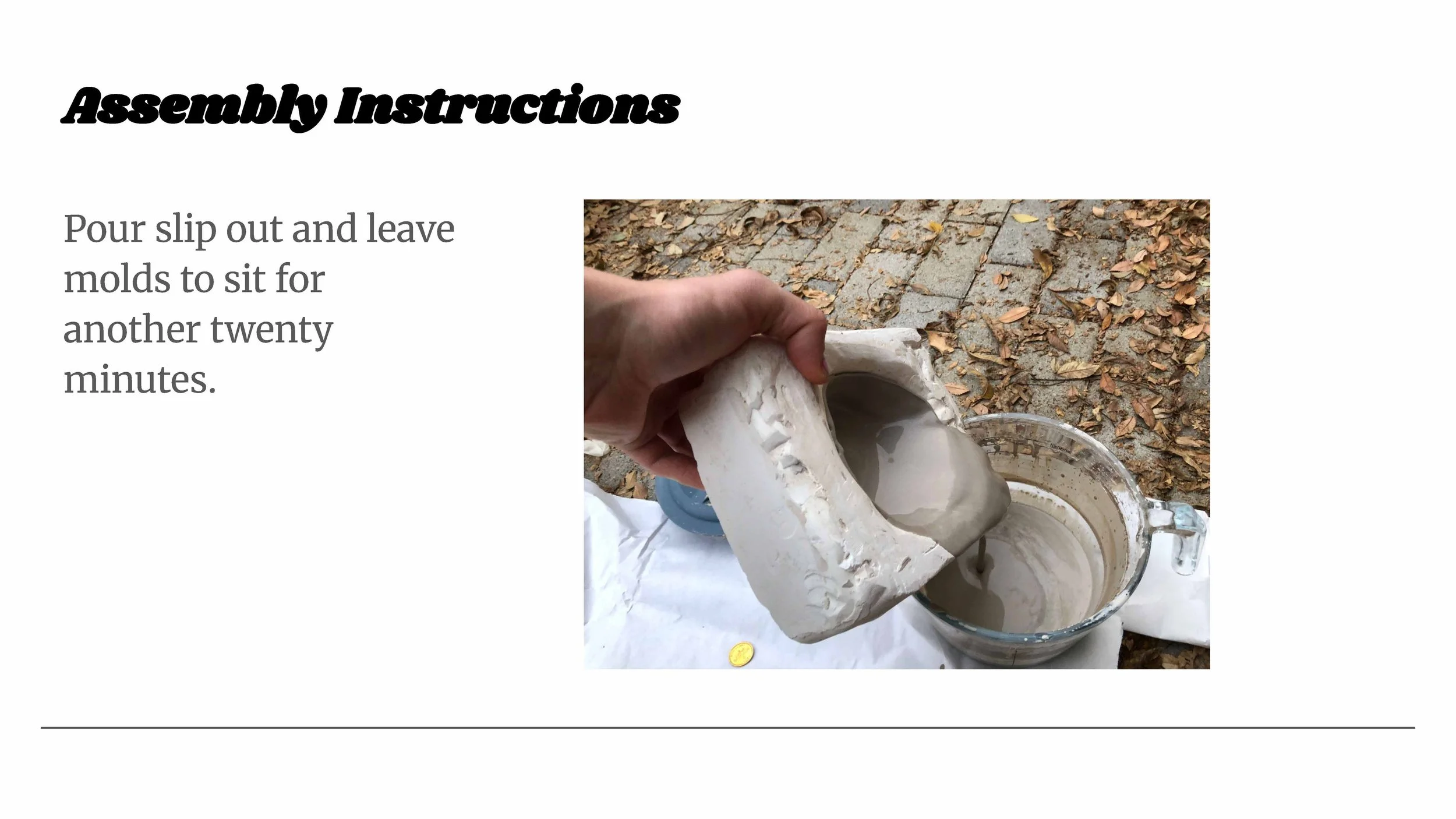

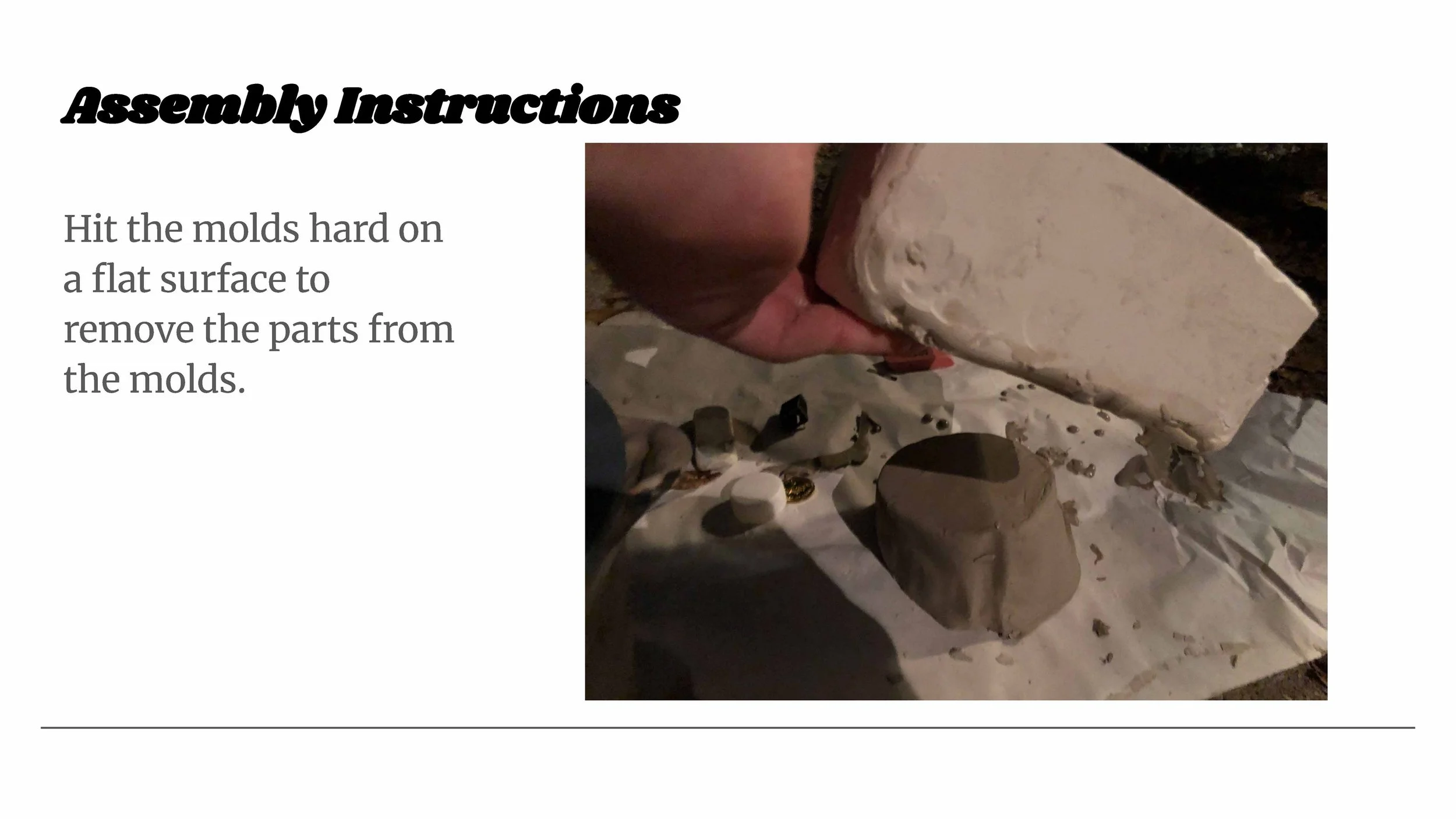

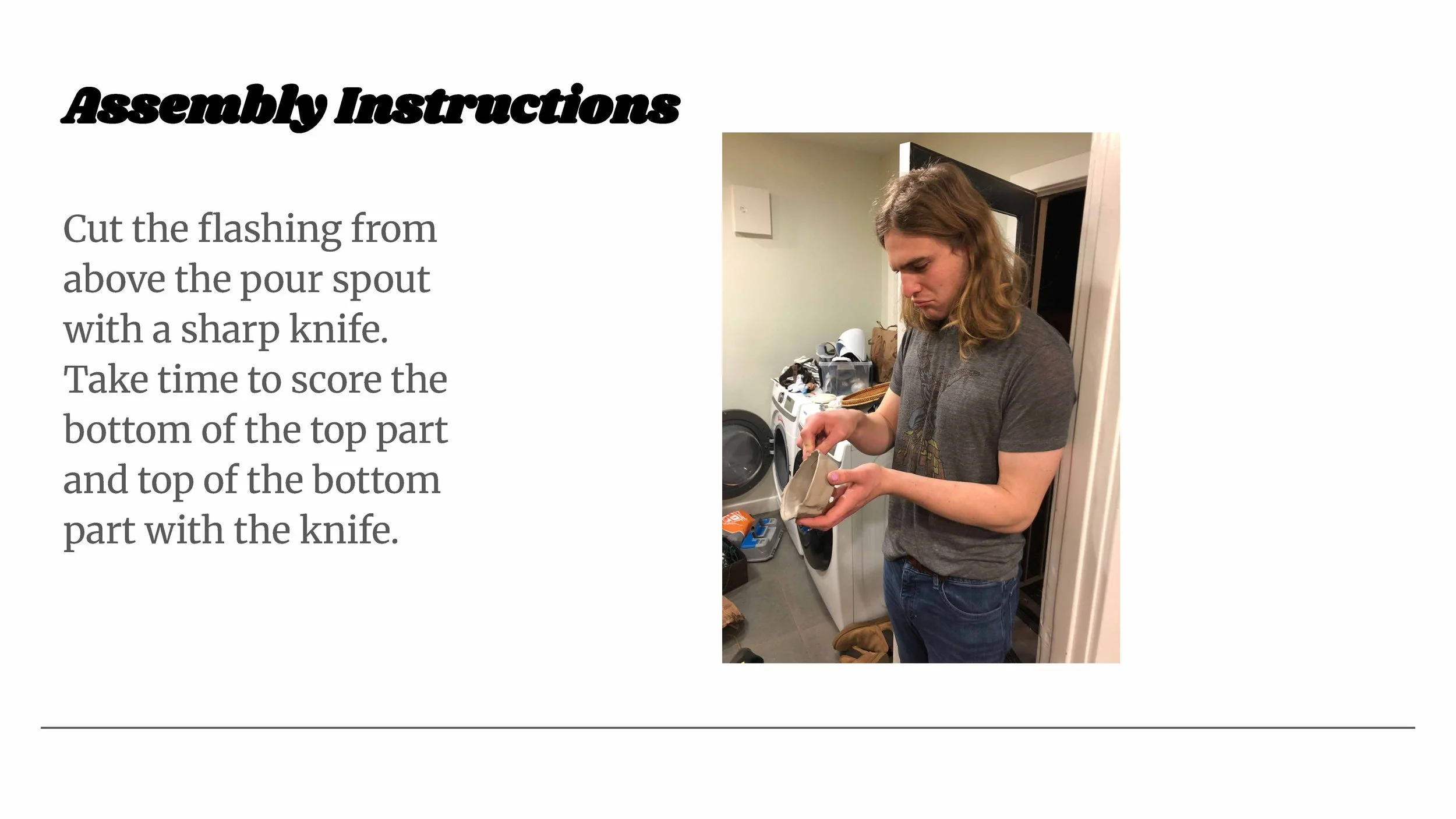

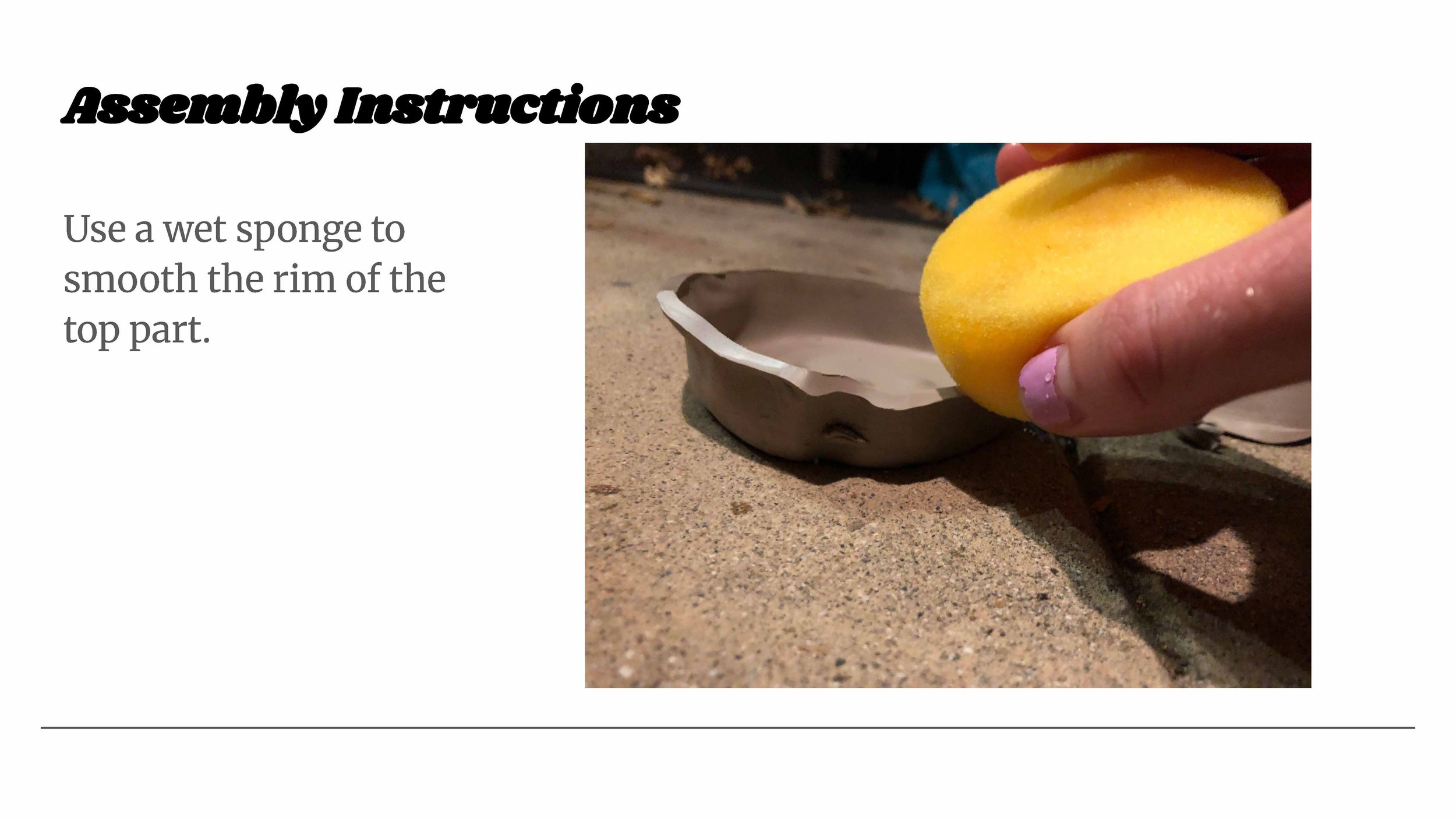

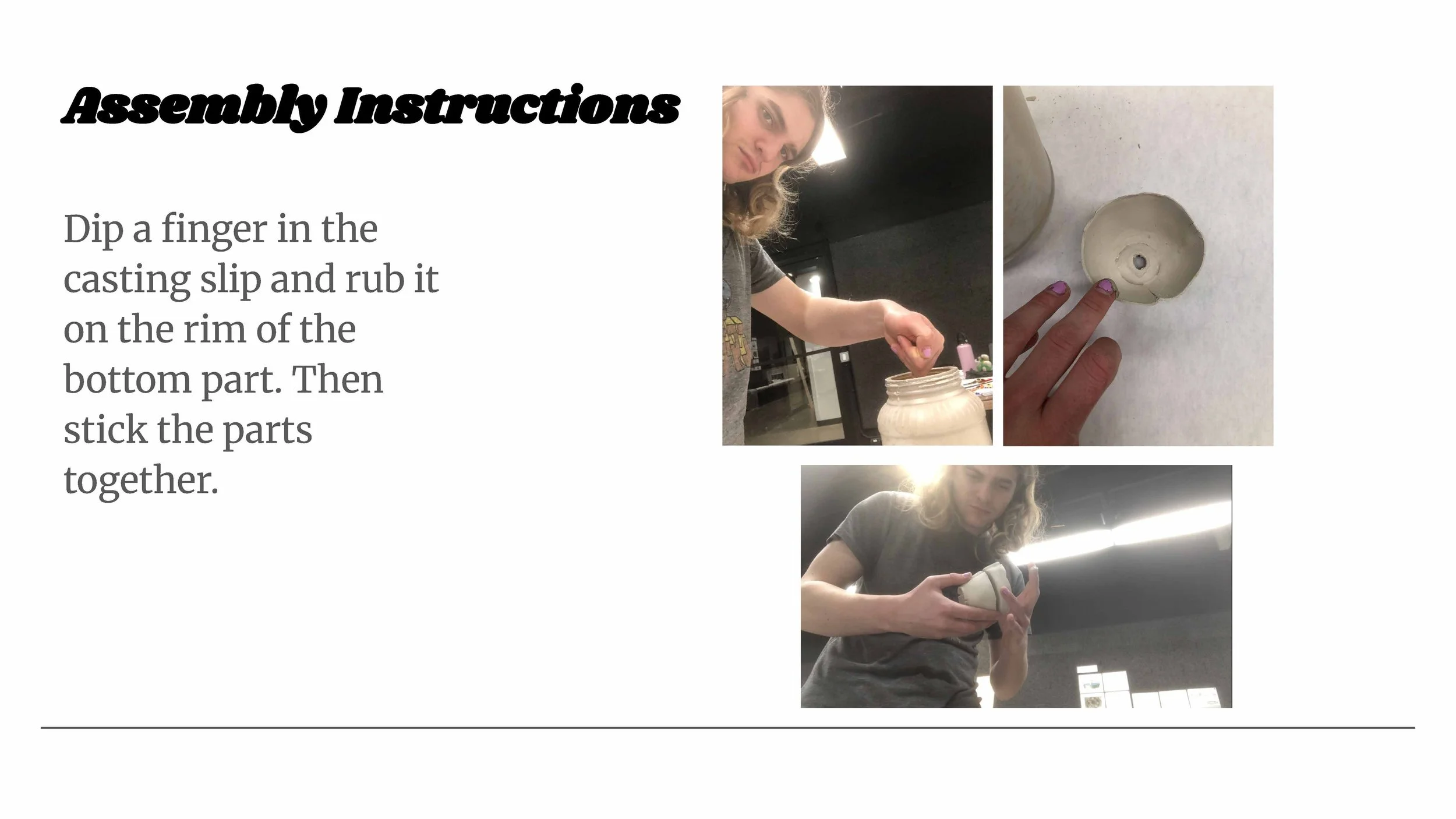

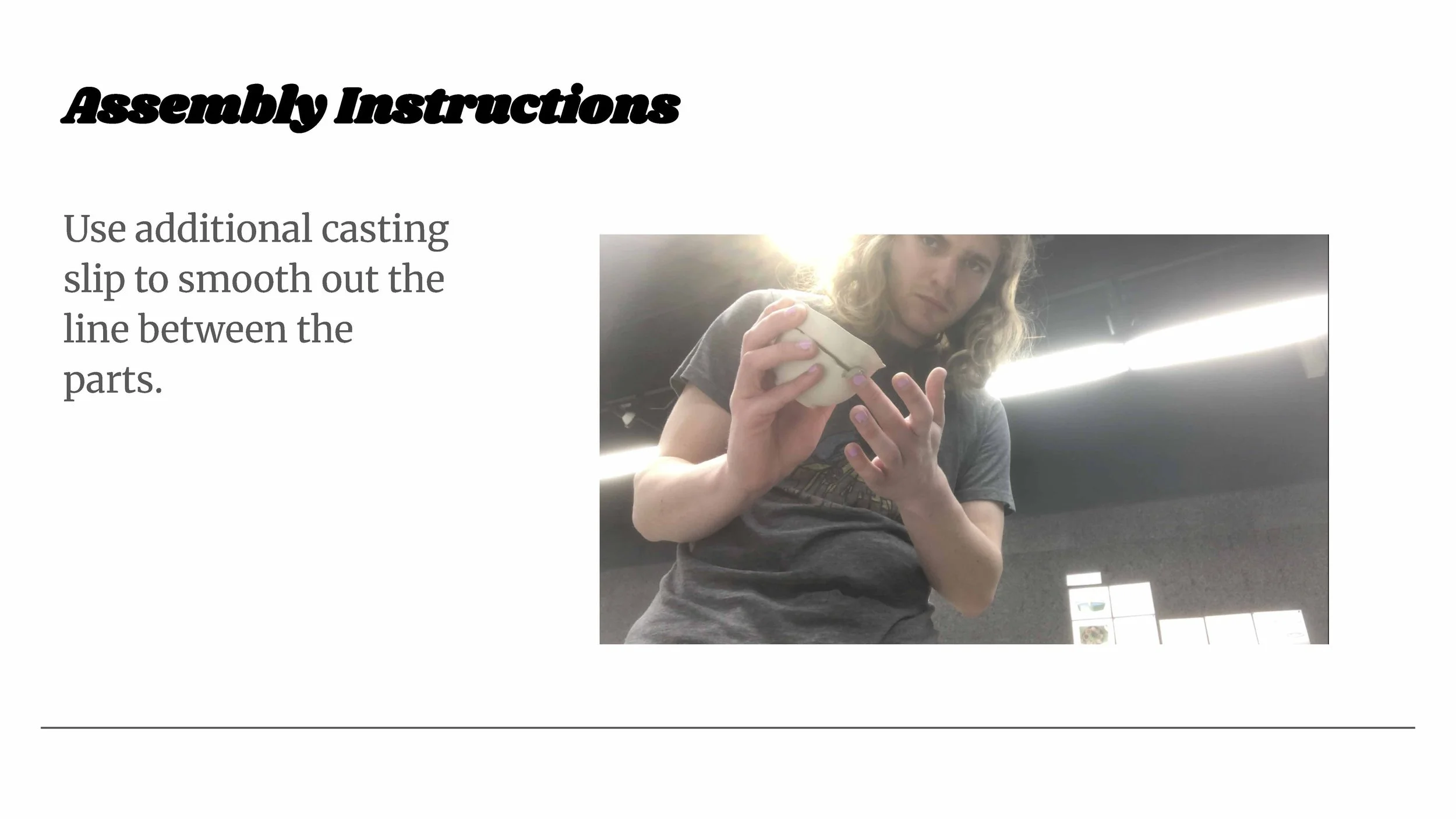

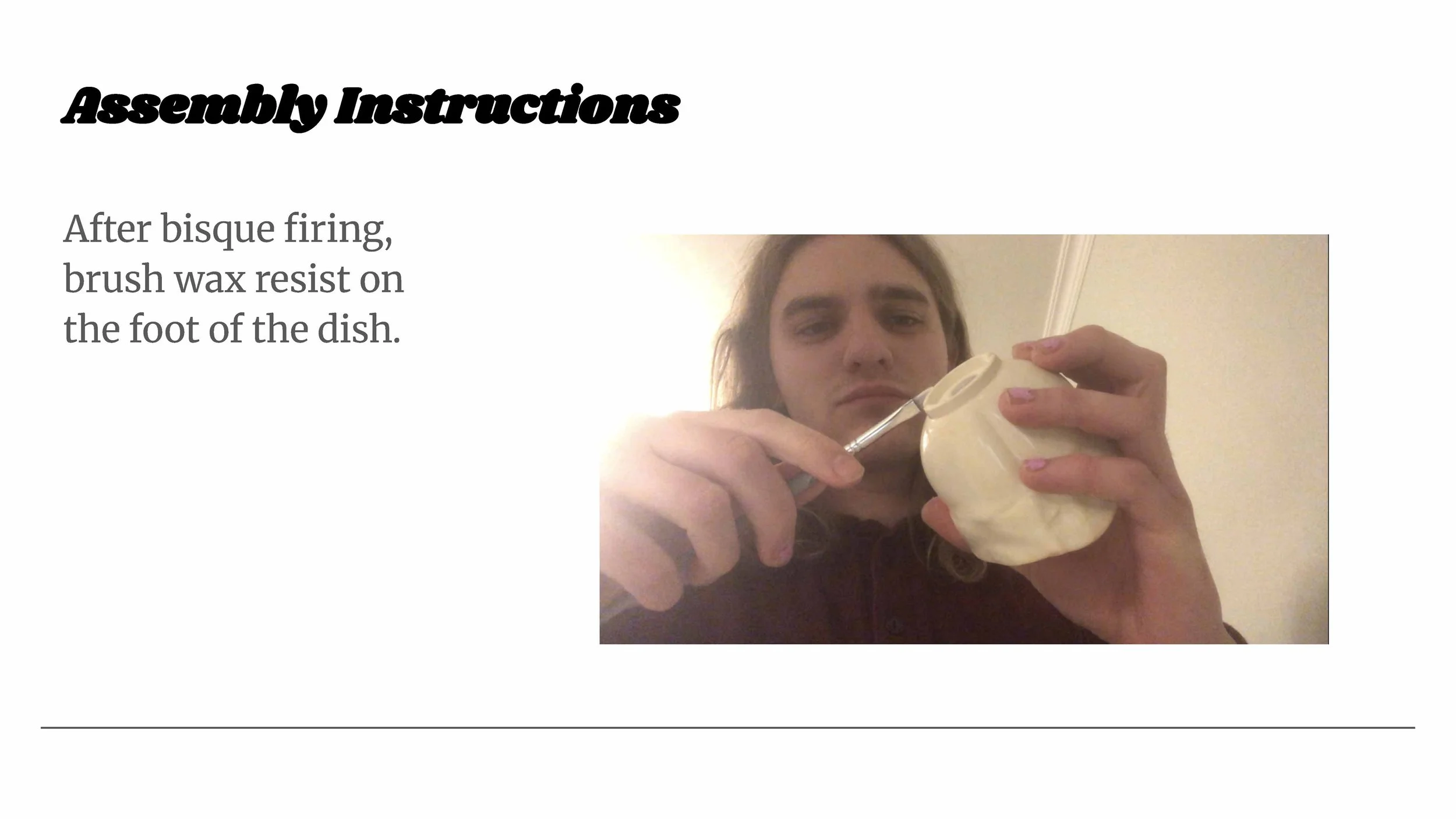

While in Thailand, I was fortunate enough to witness several industrial ceramics manufacturing processes. As part of this project, I was required to follow professional slip casting processes to produce my final presentation models, so I set to work creating the molds for my finished piece.

Mold making, Throwing, and Casting

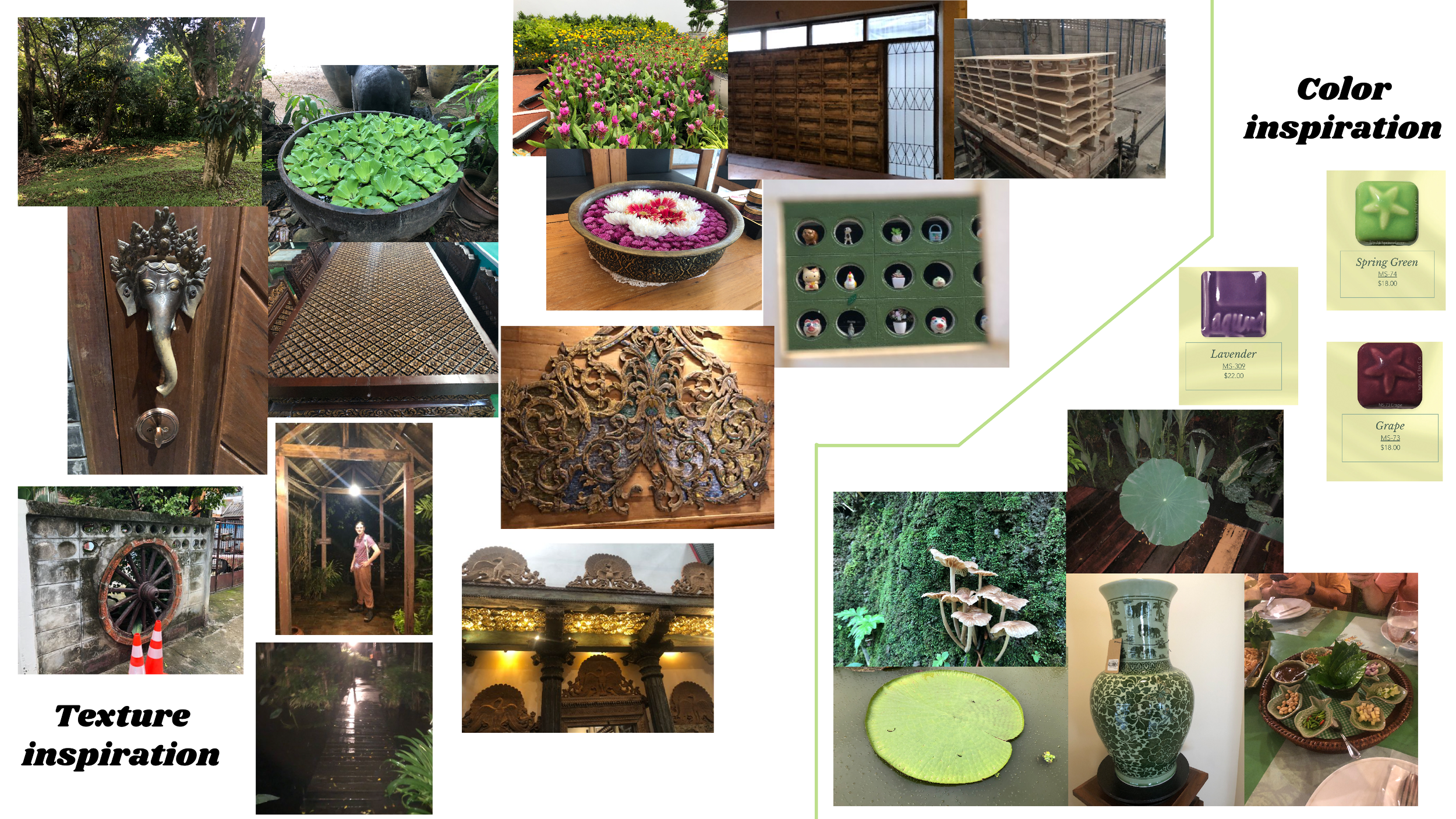

Inspiration images

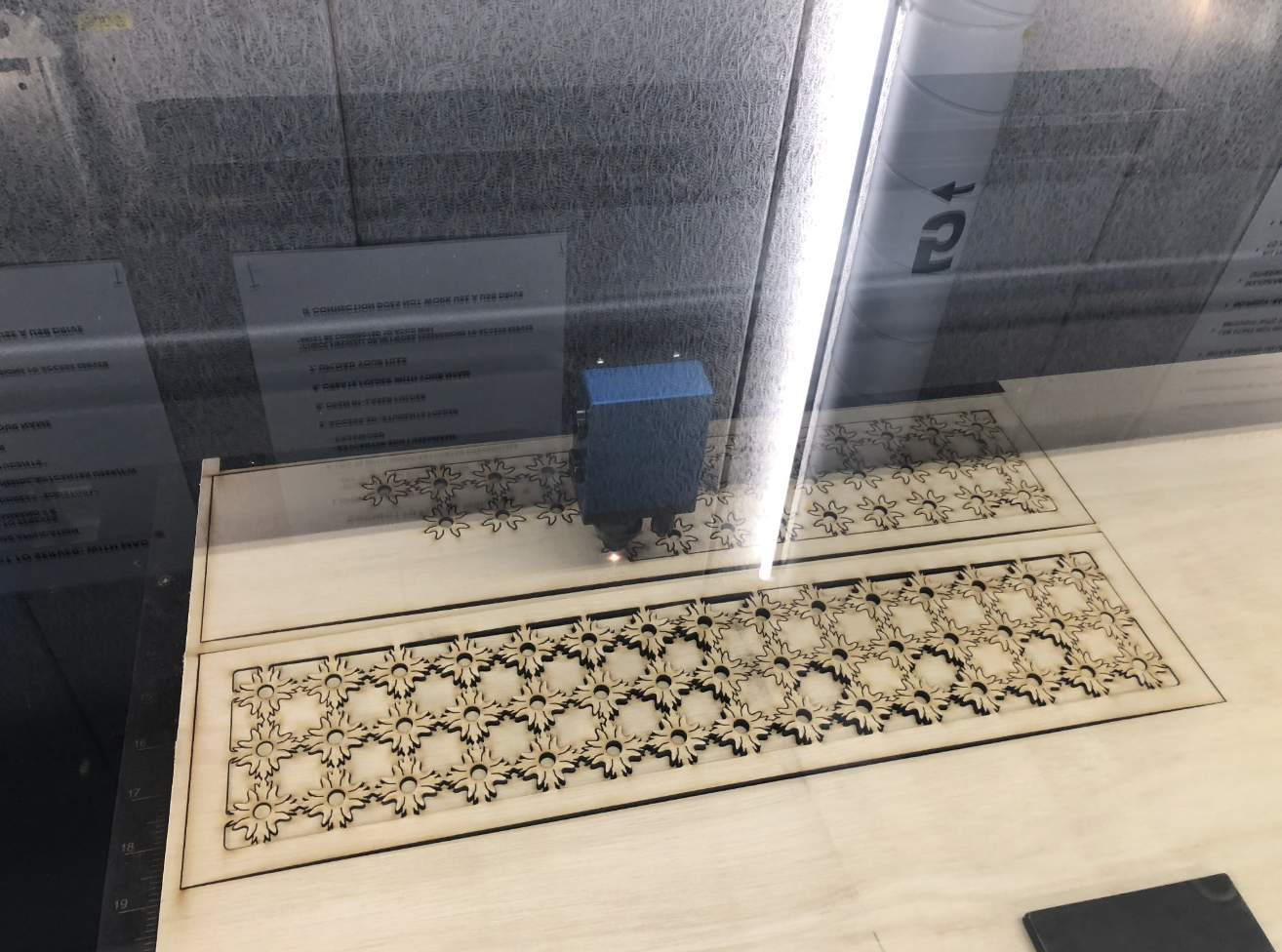

Table fabrication

I then laser cut a hole in the top piece, built a frame out of wood, wood stained all the panels and assembled everything with wood glue.